professional factory for Haitian 160t (servo) used Injection Molding Machine to Romania Manufacturer

professional factory for Haitian 160t (servo) used Injection Molding Machine to Romania Manufacturer Detail:

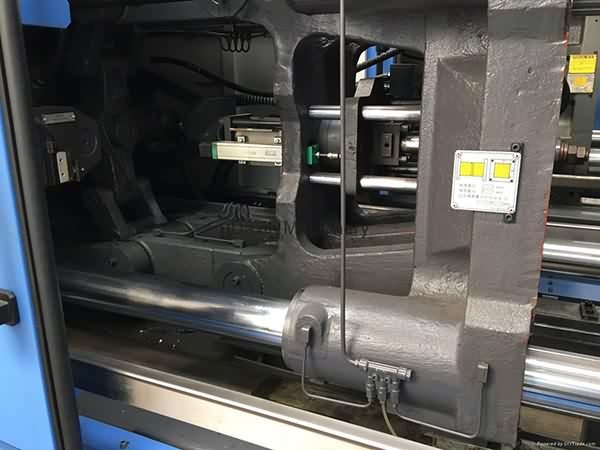

Haitian 160t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for professional factory for Haitian 160t (servo) used Injection Molding Machine to Romania Manufacturer, The product will supply to all over the world, such as: Afghanistan , Plymouth , Congo , We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

A factory of raw material of plastic goods at old Dhaka in Bangladesh.

It's tailored for the demand of high speed production.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!