professional factory for Hwa Chin 160t two-color used Injection Molding Machine to Egypt Manufacturers

professional factory for Hwa Chin 160t two-color used Injection Molding Machine to Egypt Manufacturers Detail:

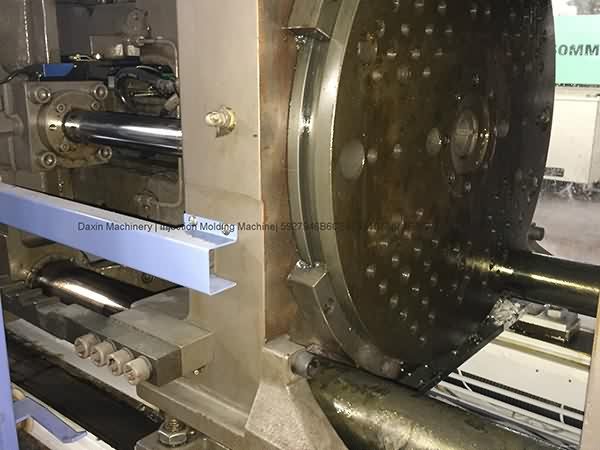

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for professional factory for Hwa Chin 160t two-color used Injection Molding Machine to Egypt Manufacturers, The product will supply to all over the world, such as: Congo , Bangkok , Turkey , With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

Plastic film crusher of MG PLAS can be used for kinds of waste plastic films such as HDPE films, LDPE/LLDPE films, PP films, PET films and PVC films, etc.

Supply ranges of Plastic film crushers in MG PLAS:

motor power:45kw/55kw/75kw/90kw

capacity range: 400kg/h to 1500kg/h for different models.

blades materials: SKD-II Korea or Japan.

main bearings position: external.

shaft: by dynamic balance testing.

machine weight range: 3000kg to 6500kg.

Configuration:

belt conveyor+ heavy wet plastic film crusher+ screw feeder.

independent control cabinet.

For more details of plastic film crusher in MG PLAS, please contact:

Mr.Gram Gao

Email: gram@vip.163.com,

Mobile&whatsapp:+86 13776255760

Skype: gramlg.

Please subscribe our YouTube channel for more updated videos.

Thank you very much.

Electric motor Armature repair, NEVER TRY THIS EVER! Electricity can and will kill you if your are not careful, if you have a bad armature, replace it, do not try to repair it, this only shows you the mechanics of an armature and this probably won't last long. I ended up using a brass brush instead, the copper did not last long, and don't forget to clean your graphite brushes with light sanding. I also put a heat resistant ring around both ends of the armature brushes cut out of tubing and glued them in, this worked good at holding the brush in place. Any time you experiment with motors they can hold a spark for a long time after you are done so make sure you watch your project for a while after to prevent any fire hazard. Again don't ever do this just replace the armature with a brand new one, or better yet get a new tool. The cost for a new tool is similar to an armature cost, this is desert island science, for those people stranded on an island with nothing but spare parts. keep inventing'

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.