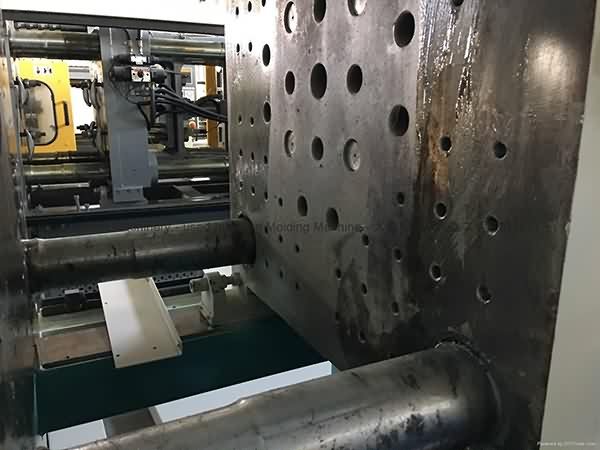

Quality Inspection for CLF-200TY used Injection Molding Machines to Lebanon Manufacturer

Quality Inspection for CLF-200TY used Injection Molding Machines to Lebanon Manufacturer Detail:

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Quality Inspection for CLF-200TY used Injection Molding Machines to Lebanon Manufacturer, The product will supply to all over the world, such as: French , Doha , Bogota , All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Contact Us For Help: https://wwa.stonecrushersolution.org/solutions/solutions.html sand casting molding machine sand casting molding machine. If you want to ...

2001 Nissei Electric, IMM, Injection Molding Machine, 45 Ton, 1.6 oz.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.