Rapid Delivery for Chuan Lih Fa CLF-950TX used Injection Molding Machine Supply to Hyderabad

Rapid Delivery for Chuan Lih Fa CLF-950TX used Injection Molding Machine Supply to Hyderabad Detail:

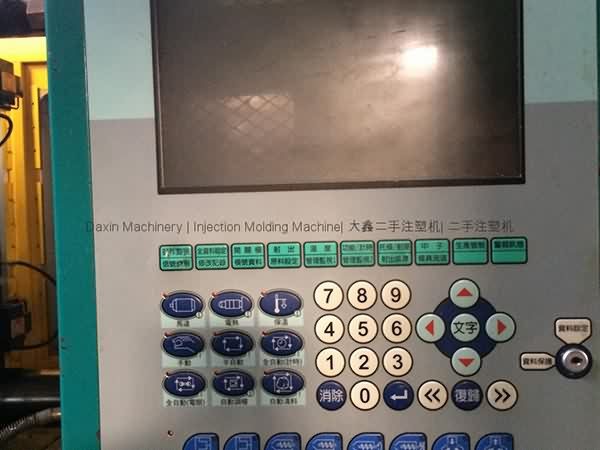

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for Rapid Delivery for Chuan Lih Fa CLF-950TX used Injection Molding Machine Supply to Hyderabad, The product will supply to all over the world, such as: Bolivia , California , Holland , Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Since the establishment in 1963, we have been developing businesses as a machine and edge tool manufacturer not only in Japan but also overseas. Our company credo "Trust" means that we are committed to acquiring technological capabilities that allow us to earn the trust of users, making products that can "respond to the trust", and fostering human resources to grow to be a company that "can gain the trust". We use special steel of a Japanese blast furnace manufacturer as raw materials for various types of blades. As of 2013, we had No.1 production volume of grass cutting blades in Japan, and manufacture and sell the high-quality products that are fully produced domestically. We also deal in a variety of products for applications in agriculture, gardening, construction and others, and have a track record of exports to the world leading brush cutter manufacturers. We take all possible measures to ensure safety as well as sharpness or durability, and are strictly checking the quality of products.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.