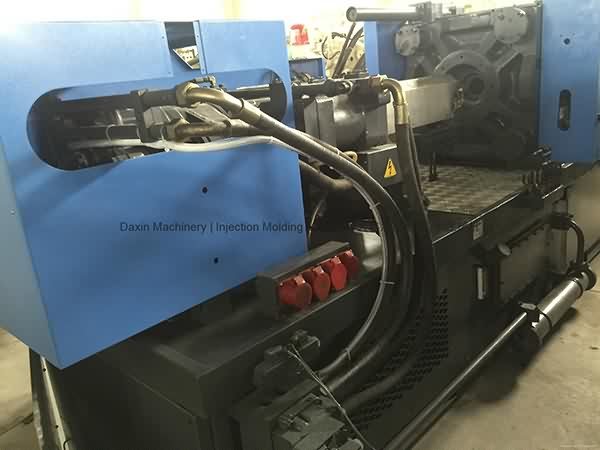

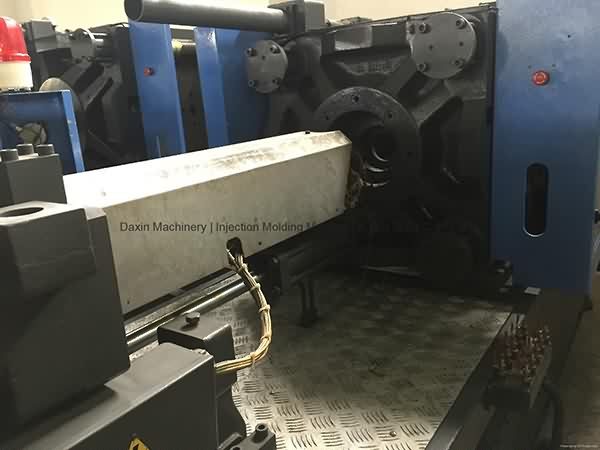

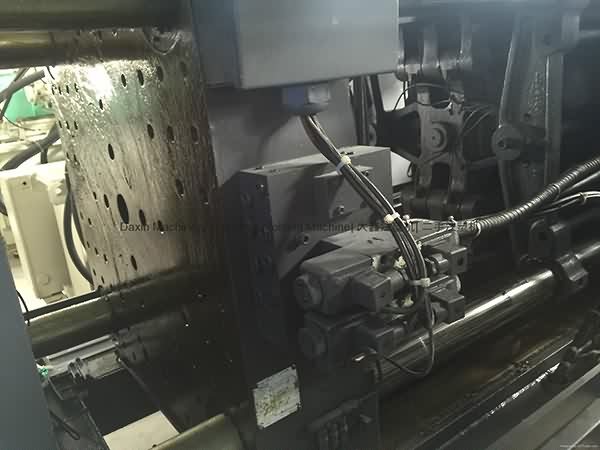

Rapid Delivery for Haitian HTF200W2 used Injection Molding Machine – All-Electric Used Plastic Machine

Rapid Delivery for Haitian HTF200W2 used Injection Molding Machine – All-Electric Used Plastic Machine Detail:

Haitian 200t used injection molding machine.

Youtube Video: https://youtu.be/9icUR6v9ilQ

Model: HTF200W2.

Year: 2006.

Screw diameter: 55/50mm.

Tie bar spacing: 520x520mm.

Two units for sale. Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

www.daxin88.com

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for Rapid Delivery for Haitian HTF200W2 used Injection Molding Machine – All-Electric Used Plastic Machine, The product will supply to all over the world, such as: Bulgaria , United Kingdom , British , Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

Pressa verticale JSW all-electric.

Faktor 3 - Defekt Producers: Quadro B (feat. Demis H and Denzity) the following tracks will apear on the release: 01 Kick it 02 Defekt 03 Striker (Feat. Zodiac) 04 ...

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.