Rapid Delivery for Mitsubishi 1300t Used Injection Molding Machine – JSW Used Injection Moulding Machine

Rapid Delivery for Mitsubishi 1300t Used Injection Molding Machine – JSW Used Injection Moulding Machine Detail:

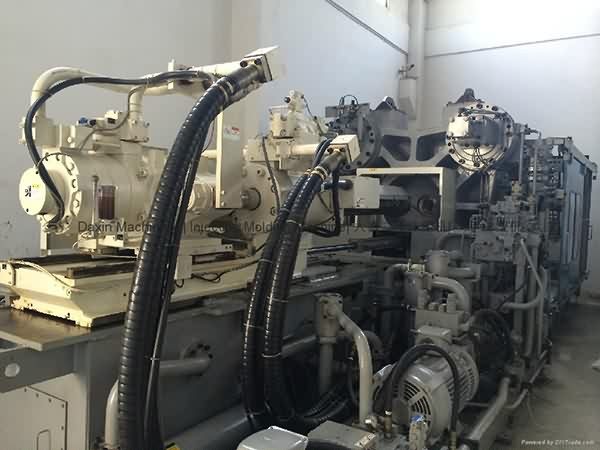

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Rapid Delivery for Mitsubishi 1300t Used Injection Molding Machine – JSW Used Injection Moulding Machine, The product will supply to all over the world, such as: Thailand , United Kingdom , Paraguay , We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

SOGUTECH.COM

Watch this video to learn more about Injection Molding and how it's used in 3D printing. For more information about PolyJet Technology, visit: ...

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!