Reasonable price CLF-1000T (servo) used Injection Molding Machine to Southampton Factories

Reasonable price CLF-1000T (servo) used Injection Molding Machine to Southampton Factories Detail:

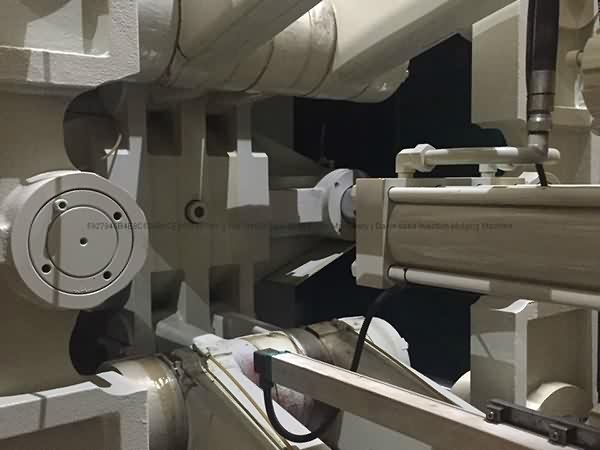

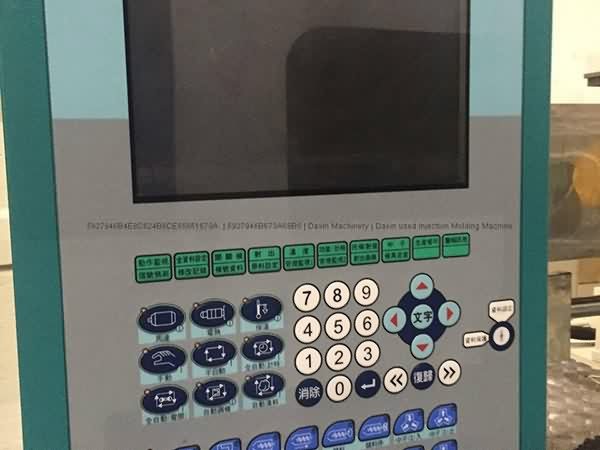

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for Reasonable price CLF-1000T (servo) used Injection Molding Machine to Southampton Factories, The product will supply to all over the world, such as: UAE , azerbaijan , Nairobi , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

Manufacturer,Distributor,Exporters & Supplier Of World Class Machinery (040-64646688)

Blow molding machine for plastic panel

Good quality and best price can make your needs

It is a special machines used for producing products with High Molecular Weight High Density

Polyethylene (HMWHDPE) as the raw material, including oversize plastic wall panels,door panels,ocean buoys,safety barriers for highway,athletic equipments,and plastic products of recreational facilities.The machines is designed and manufactured in accordance with standards of similar machine models of Germany,and this machine model has the optimized performance price ratio in the world.

TDB160E is an accumulation and injection type extrusion blow molding machine which can produce plastic door panels and plastic desktop panels.It has reasonable structure and steady and reliable performance.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!