Reasonable price Haitian 250t (servo) used Injection Molding Machine to Austria Factories

Reasonable price Haitian 250t (servo) used Injection Molding Machine to Austria Factories Detail:

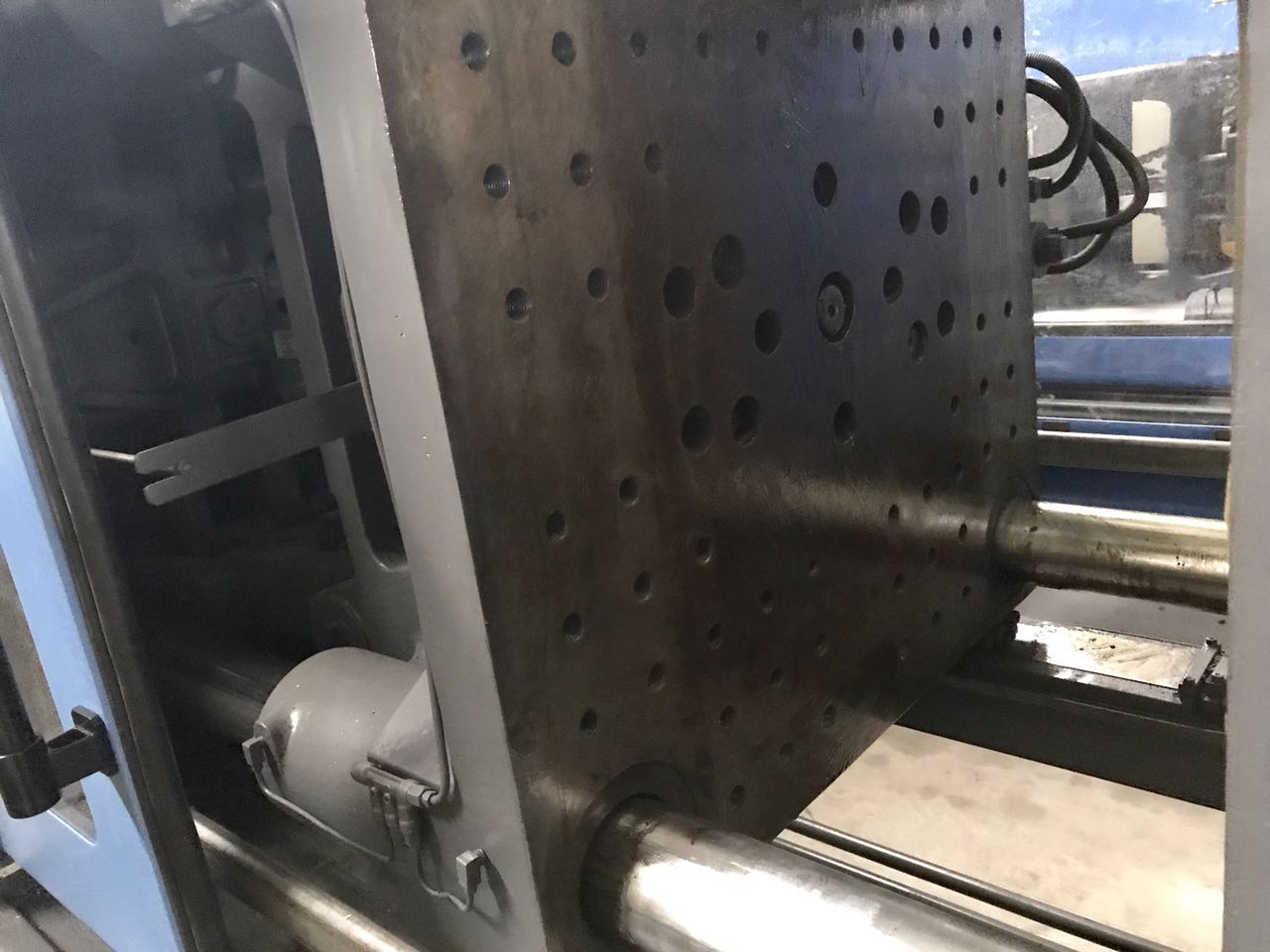

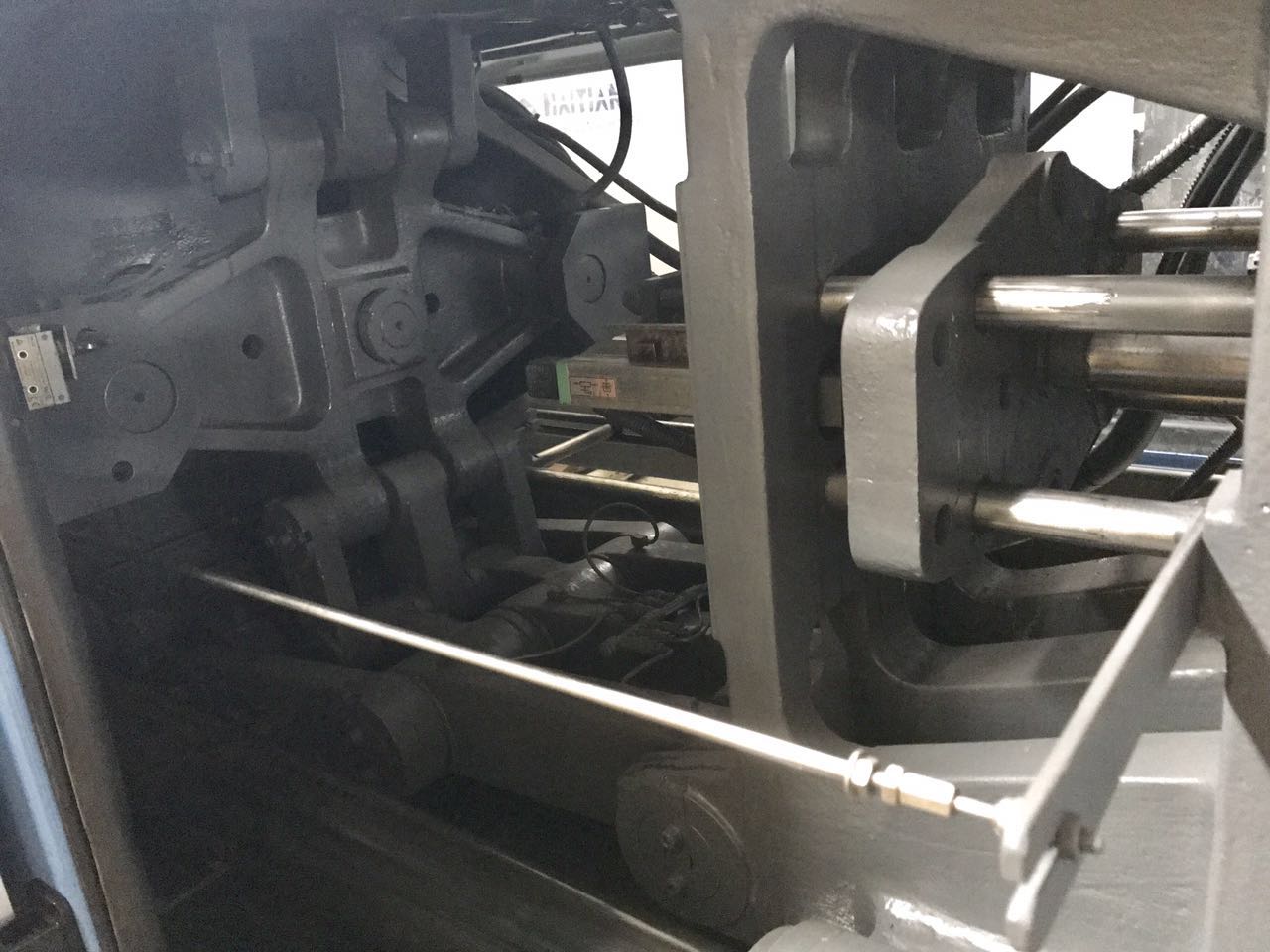

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Reasonable price Haitian 250t (servo) used Injection Molding Machine to Austria Factories, The product will supply to all over the world, such as: Hamburg , Costa rica , Libya , We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

© Copyright by https://www.youtube.com/user/djdennytv2013

DJDennyTV2013 pres. + Infos : FULL HD - 1080p50 & in 5.1ch

แสดงขั้นตอนการใช้ เครื่องCNC Milling กัดขึ้นรูปชิ้นงาน ให้เป็น รูปทรงใบพัดของเครื่องจักรกล โดยวิธีการทำจะเริ่มตั้งแต่การออกแบบสร้างโมเดล3D ในโปรแกรม CAD/CAM เพื่อกำหนดตั้งค่าระยะพิกัดในการการกัดเจาะ ก่อน จากนั้นจึงนำวัสดุ ก็คือ ก้อน MC ไนลอน หรือ Pom สีดำ มาตัดให้ได้ตามขนาดและน้ำหนักที่กำหนด แล้วทำการจับยึดตั้งตำแหน่งชิ้นงานที่ฐานเครื่องCNC แล้วจึงสั่งเดินเครื่อง ไปจนเสร็จ

5 axis cnc mill | 5 axis machining | aluminum machining | c and c machine | c&c machine | c&c machining | cac machine | cc machine | cdc machine | cdc machines | cmc machine | cmc machines | cn machine | cna machine | cnc company | cnc fabrication | cnc lathe manufacturers | cnc machine companies | cnc machine manufacturers | cnc machine precision | cnc machine products | cnc machine shop | cnc machine stand for | cnc machining and manufacturing | cnc machining equipment | cnc machining inc | cnc machining prototype | cnc machining services | cnc machinist | cnc manufacturing | cnc manufacturing companies | cnc manufacturing process | cnc mill manufacturers | cnc milling company | cnc milling services | cnc plastic machining | cnc precision | cnc precision machining | cnc production | cnc production machining | cnc products | cnc router manufacturers | cnc router table | cnc routing service | cnc screw machine | cnc service | cnc shops | cnc swiss machine | cng machine | cnn machine | cns machine | computerized carving machine | computerized wood carving machine | custom cnc | custom cnc machining | custom cnc parts | custom machine shop | custom machined parts | custom machining | custom machining services | high speed machining | large machining | machine company | machine equipment | machine service | machine shop | machine shop tools | machine shop work | machined parts | metal machine | metal machine shop | ncn machine | online cnc machining | online machine shop | precision cnc | precision cnc machining | precision cnc milling | precision machine shop | precision machining | production cnc | production machine | prototype machine shop | prototype machining | screw machining | shop cnc machine | small c and c machine | swiss cnc | swiss machine | tnc machine | turning machine | used machine shop equipment | used machining centers | vertical cnc | vertical machine | wood c and c machine

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.