Reasonable price Mitsubishi 1300t Used Injection Molding Machine to Armenia Manufacturers

Reasonable price Mitsubishi 1300t Used Injection Molding Machine to Armenia Manufacturers Detail:

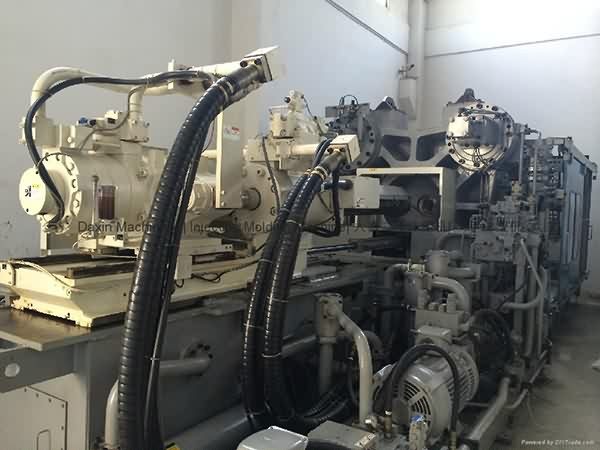

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Reasonable price Mitsubishi 1300t Used Injection Molding Machine to Armenia Manufacturers, The product will supply to all over the world, such as: Belize , Bulgaria , Saudi Arabia , With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beauty and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

https://plastiwin.com/equipment-brands-we-offer/ Used 337 Ton Battenfeld EcoPower 300 All Electric Injection Molding Machine:

* Brand: Battenfeld

* Model: EcoPower 300

* Tonnage (Metric/US): 300/337

* Year of Mfg.: 2013

* Screw Diameter: 65mm

* Shot Size: 29 oz. (PS)

* Tie Bar Spacing: 30.3" x 28.35"

* Mold Height (Min/Max): 13.78" x 29.5"

* Injection Pressure: 21131

Used Rajoo PP Film Machine. Plastic Film Extruder For Sale In Karnataka

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.