Reliable Supplier Chen Hsong Super Master SM450TS used Injection Molding Machine – Japan Injection Molding Machine

Reliable Supplier Chen Hsong Super Master SM450TS used Injection Molding Machine – Japan Injection Molding Machine Detail:

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

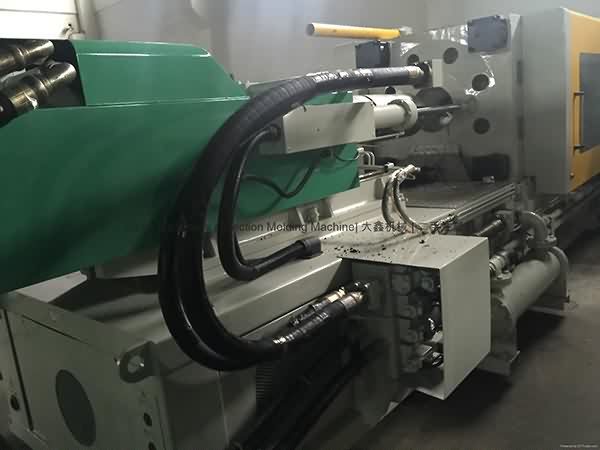

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Reliable Supplier Chen Hsong Super Master SM450TS used Injection Molding Machine – Japan Injection Molding Machine, The product will supply to all over the world, such as: Guatemala , Malaysia , Honduras , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

1. The products of IB-Series have smooth-even mouth, great sealing, round and smooth body and bottom, superior quality, and no seam mark. The machine is most suitable for manufacturing high quality products.

2. The mold design adopts the method of common mold base. Only by changing the mold parts, the product's shape, weight, or even the length can be changed. It saves time on mold alignment and doesn't require great expertise on mold changeover. Thus, it reduces the mold cost on manufacturing a wide range, but low volume of different applications.

3. The mechanical design is based on the blueprint of general-purpose injection molding machine. Hence, with general knowledge of injection molding machine, no matter machine operation or maintenance work can be handled with ease.

4. Applied materials include PC, PP, PE, PS, AS, PMMA, K-Resin, PET, PETG, TPR, PES, PCO and NYLON.

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, (for which the process is called diecasting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!