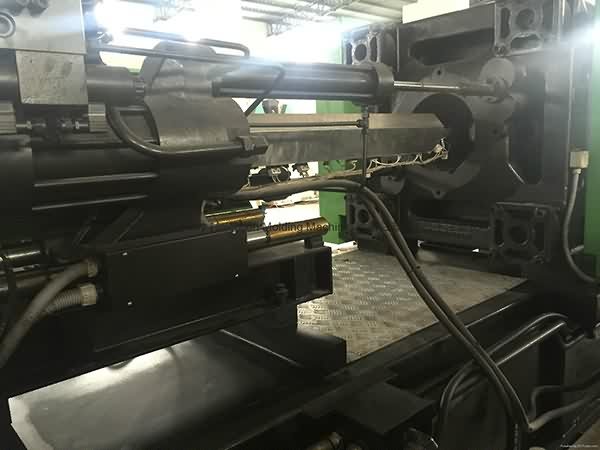

Reliable Supplier Donghua 320t (variable pump) used Injection Molding Machine for Thailand Factory

Reliable Supplier Donghua 320t (variable pump) used Injection Molding Machine for Thailand Factory Detail:

Taiwan Donghua 320t injection molding machine (Variable pump).

YoutubeVideo: https://youtu.be/6LtP9BF6UnA

Model: TTI-320F2V.

Year: 2012.

Screw diameter: 55mm.

Tie bar spacing: 660x660mm.

Machine is in good running condition with variabl pump. Interested customer can inspect machine.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for Reliable Supplier Donghua 320t (variable pump) used Injection Molding Machine for Thailand Factory, The product will supply to all over the world, such as: Korea , Ottawa , Japan , We are adhering to the philosophy of "attracting customers with the best products and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

THE MACHINE HAS BEEN SOLD

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.