Reliable Supplier Haitian 200t (servo) used Injection Molding Machine – Servo Injection Molding Machine

Reliable Supplier Haitian 200t (servo) used Injection Molding Machine – Servo Injection Molding Machine Detail:

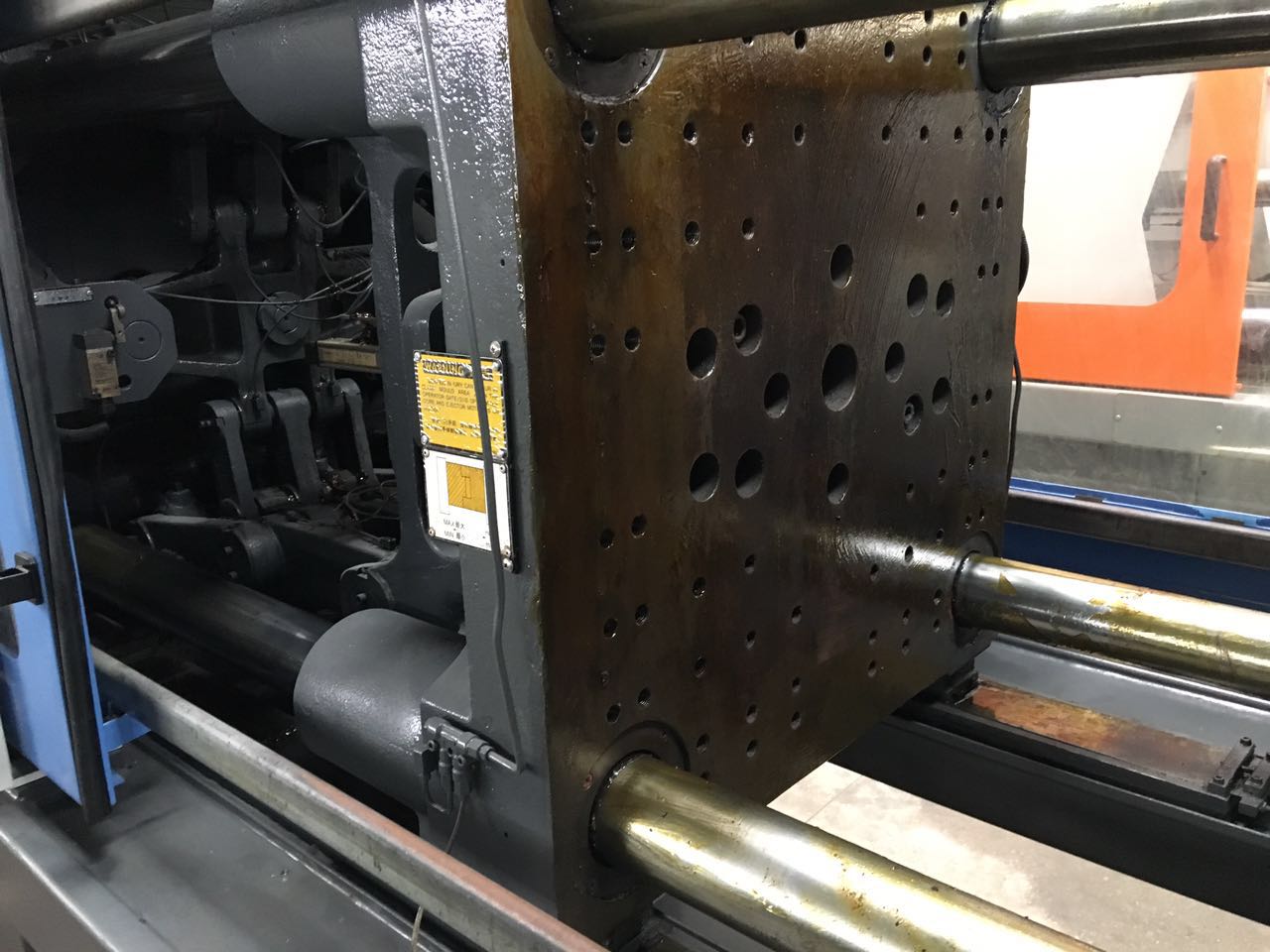

Haitian 200t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for Reliable Supplier Haitian 200t (servo) used Injection Molding Machine – Servo Injection Molding Machine, The product will supply to all over the world, such as: Bangladesh , Lyon , Finland , We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

Prometech Software, Inc.

Particleworks Demo

https://www.prometech.co.jp/

This video is taken in Chinaplas2016 Shanghai. Machine in the video is our latest model: HFTF-80T which is designed special for high yield production need with forming area of 762*470mm. Sample cup in the video is pet material with 92.5mm diameter.

APPLICATION:

HFTF-80T-H Automatic Thermoforming Machine suitable for PP, HIPS, PVC , PET,ETC. sheet.

Main Technical Specification

1- Max. Forming Area 762×470mm

2- Max. Forming Depth 180mm

3-Clamping Force 650KN

4- Max Sheet Width Range 820mm

5- Sheet Thickness 0.4-2.5mm

6- Air Pressure 0.7-0.85mpa

7- Water Consumption 50L/min

8- Air Consumption 5000L/min

9- Max.No-load Speed 42 Cycles/min

10- Power (Three Phase Four Wire) 3×380V+N+PE.50HZ

11- Heating Power 150kw

12- Main Motor Power 15kw

13- Stretch Motor Power 15kw

14- Feeding Motor Power 5.5kw

15- Machine Weight 15500kg

16- Dimension 13000×4500×3800mm

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.