Reliable Supplier Niigata 450t All-electric used Injection Molding Machine to Honduras Manufacturers

Reliable Supplier Niigata 450t All-electric used Injection Molding Machine to Honduras Manufacturers Detail:

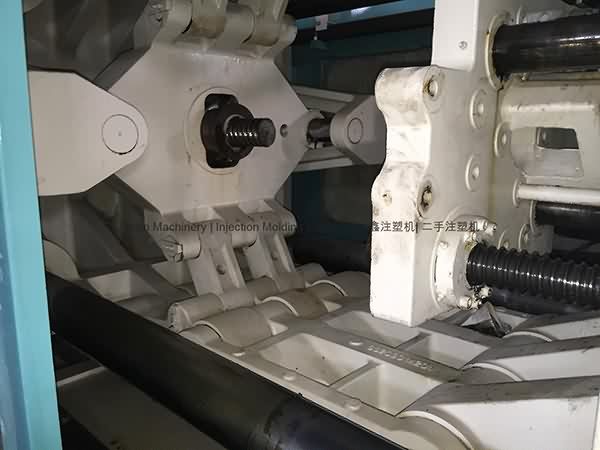

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Reliable Supplier Niigata 450t All-electric used Injection Molding Machine to Honduras Manufacturers, The product will supply to all over the world, such as: Sweden , Algeria , Lesotho , Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

Mold-Masters Melt-CUBE Direct Side Gating Hot Runner System with TIM-Plastik Mold for Medical Injection Molding of a 20ml Syringe Barrel with Luer Lock -- as see live at ARBURG Technology Days in Loßburg, Germany (March 13-16, 2013)

About Elite Decor Industry www.elitedecor.ua:

As of 2002, Elite Decor Group is a manufacturer of architectural moldings made of polymeric materials.

In 2008, Investment Group Building Products European S.A. decided to launch in Ukraine, which is located at the geographical center of Europe, a modern hi-tech plant for manufacturing polymer products.

The decision was prompted by a growing demand for decorative moldings in the markets of Europe, the CIS, Middle East, Africa and Asia.

For this purpose, Investment Group Building Products European S.A., which has manufacturing enterprises in Europe, Malaysia, China and South America, acquired the company Elite Décor Group and, on its basis, launched a plant – Elite Decor Industry – which adopted the best practices developed by the above-mentioned enterprises over several previous decades.

Due to this plant, the company gained logistical advantages over Asian manufacturers and that made it possible to respond most promptly to the growing demand of the construction market and, at the same time, to maintain efficient operations in the markets of Europe, the CIS, Middle East, Africa and Asia.

Elite Decor Industry is a unique R&D, technology and manufacturing complex, which includes:

- Design department;

- Polymeric materials laboratory;

- Equipment design and development department;

- And polymer production plant

Today, Elite Décor Industry is a large enterprise, which provides jobs for more than 700 qualified staff employed at our production facility and partner companies.

The design unit develops new elements for our collections, as well as interior and exterior concepts. Besides, this department develops customized collection designs for our clients.

The polymeric materials laboratory controls the quality of raw materials used the production process, improves it and monitors the quality of finished goods on an ongoing basis.

The Equipment design and development department designs and manufactures equipment for high pressure polyurethane foam injection, automated lines for manufacturing PU products, CNC machines and other equipment.

Polymer production plant Elite Decor Industry is a fully automated facility, which manufactures annually over 3.7 million decorative elements for interior and exterior.

Our enterprise has a complete production cycle, ranging from making 3d models and casting molds to finished products.

The warehouse stock of Elite Décor Industry features 1800 titles and the range of pre-fabricated forms includes over 5000 titles.

The only other manufacturers’ product used in our technological chain – raw material for producing top-quality polyurethane and acryl-based items – comes from the world’s leading companies in this field – Dow Chemicals and BASF.

The plant can use all up-to-date technologies of making products from polyurethane, polystyrene foam, hybrid and composite polymeric materials. Manufacturing automation minimizes the impact of human factor on the quality of finished products.

Each stage of production is operated by qualified specialists.

Elite Décor Industry successfully works with large-sized fiberglass and other composite products more than 2 meters in diameter.

One of the areas of the company’s operation is the production of beams, panels and connecting elements realistically imitating the texture of wood of various species and degrees of processing.

On the basis of polystyrene foam and acrylic multicomponent polymer with natural marble filling Elite Décor Industry manufactures a range of facade-finish products, including customized items with no size restrictions.

Elite Décor Industry manufactures products from high density extruded polystyrene, including with raised impressions and decorative films.

Elite Décor Industry offers OEM and Private Label services.

Quality control at all stages of the production cycle, from raw material to packaging, meets the ISO 9001 standards.

To advertise and promote our products we created special marketing instruments - demonstration stands, boxes with product samples, 3D models, catalogs, installation and usage guides.

Today, we supply our products to 45 countries and the number is steadily growing.

The fundamental corporate vision of Elite Décor Industry is customer-orientation in providing top-quality products.

Elite Décor Industry is a major manufacturing and trading enterprise with its own cutting-edge facilities that produce stucco décor collections from polyurethane and façade decorations under the world-renowned trademarks: Grand Décor, Harmony, Prestige Décor, Prestige Décor LED, Deco Wood, Tesori, Art, Arxat and many others.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!