Reliable Supplier Sumitomo 130t All-Electric used Injection Modling Machine for Slovakia Factory

Reliable Supplier Sumitomo 130t All-Electric used Injection Modling Machine for Slovakia Factory Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

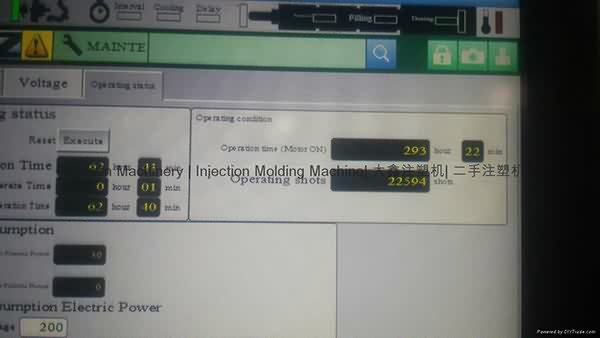

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Reliable Supplier Sumitomo 130t All-Electric used Injection Modling Machine for Slovakia Factory, The product will supply to all over the world, such as: Honduras , Iran , Luxemburg , We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

For more than 25 years, R&B Plastics Machinery (www.rbplasticsmachinery.com) has excelled at working with companies to develop unique and creative ...

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034473?

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.