Reliable Supplier Toshiba 1300t (wide platen) used Injection Molding Machine – Japanese Used Injection Molding Machine

Reliable Supplier Toshiba 1300t (wide platen) used Injection Molding Machine – Japanese Used Injection Molding Machine Detail:

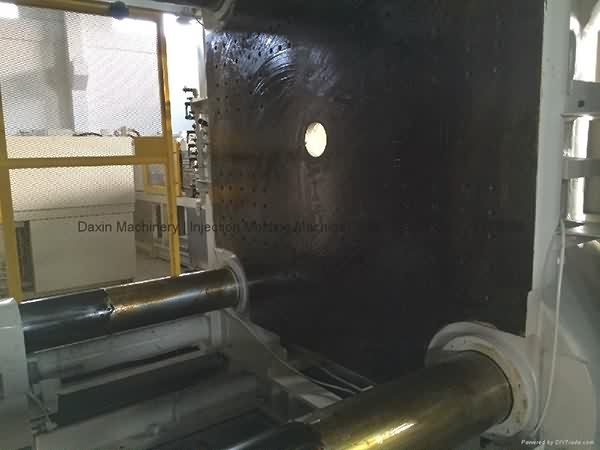

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for Reliable Supplier Toshiba 1300t (wide platen) used Injection Molding Machine – Japanese Used Injection Molding Machine, The product will supply to all over the world, such as: Romania , Indonesia , Estonia , Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

The goal of this project was to take a high volume production job that involved overmolding metal inserts into a plastic part and automate it with a robot.

how to manufacture the PVC electrical fitting through Injector Machine

Please subscribe my channel for more videos.

Roads and engineering stuff.

-~-~~-~~~-~~-~-

Please watch: "folding houses"

-~-~~-~~~-~~-~-

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!