Renewable Design for Chuan Lih Fa CLF-950TX used Injection Molding Machine Supply to Lyon

Renewable Design for Chuan Lih Fa CLF-950TX used Injection Molding Machine Supply to Lyon Detail:

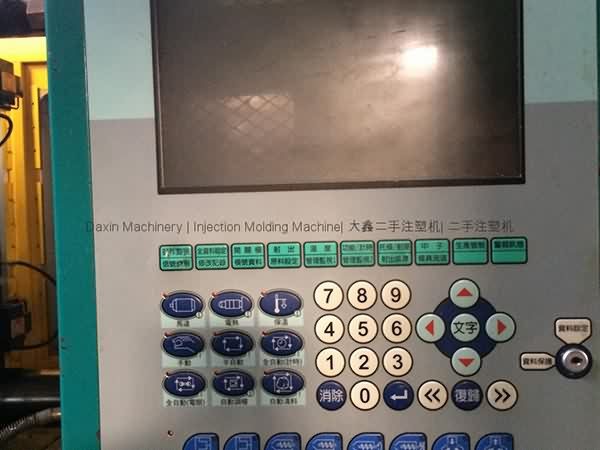

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

To create far more benefit for customers is our company philosophy; customer growing is our working chase for Renewable Design for Chuan Lih Fa CLF-950TX used Injection Molding Machine Supply to Lyon, The product will supply to all over the world, such as: Greece , Zimbabwe , Bolivia , Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

Injection molding of a pen cap connector part from raw materials to finished pen cap part. This video features my new injection molding setup utilizing a 1 ton ...

Mould steel: P20 core and cavity

Hardness: 40 HRC

Machine: 1000 ton

Visit https://www.usedmoldmarket.com/

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.