Renewable Design for Haitian 250t (servo) used Injection Molding Machine – All-Electric Used Plastic Machinery

Renewable Design for Haitian 250t (servo) used Injection Molding Machine – All-Electric Used Plastic Machinery Detail:

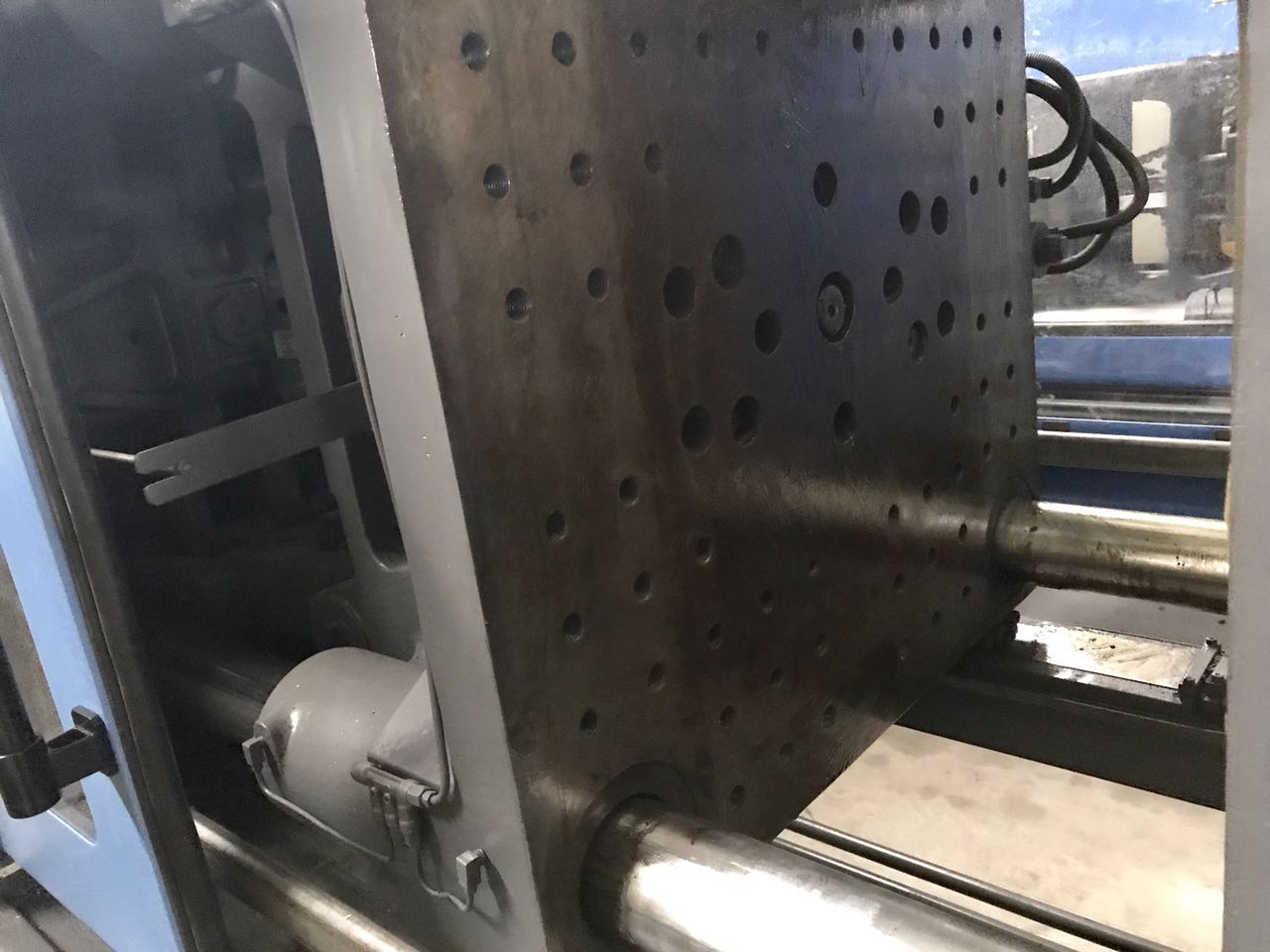

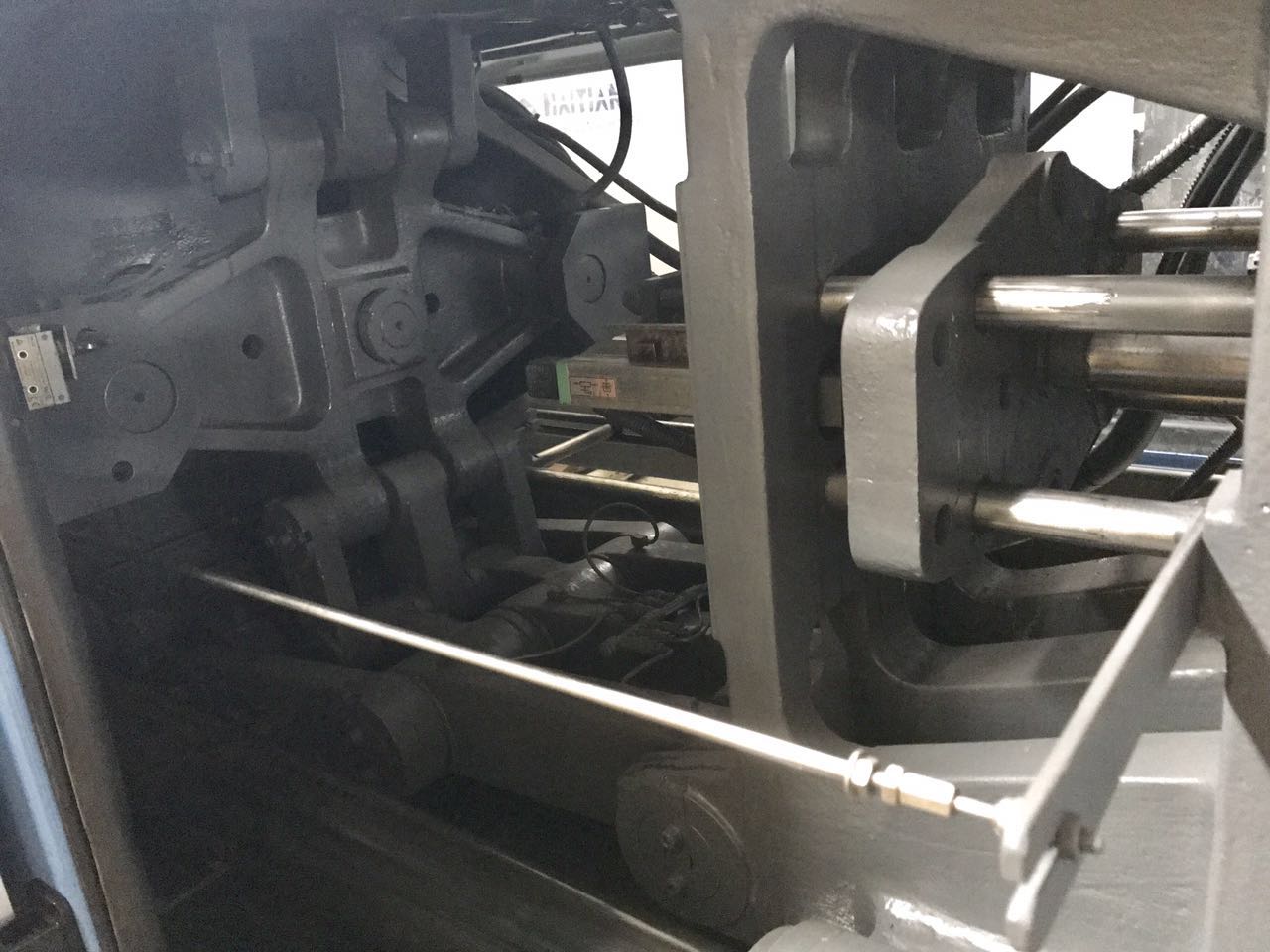

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Renewable Design for Haitian 250t (servo) used Injection Molding Machine – All-Electric Used Plastic Machinery, The product will supply to all over the world, such as: Mauritius , Finland , Uruguay , During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Information about the Dorman Fuel Line Repair Kit, part number 800-300.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.