Renewable Design for Haitian HTF200W2 used Injection Molding Machine to kazan Importers

Renewable Design for Haitian HTF200W2 used Injection Molding Machine to kazan Importers Detail:

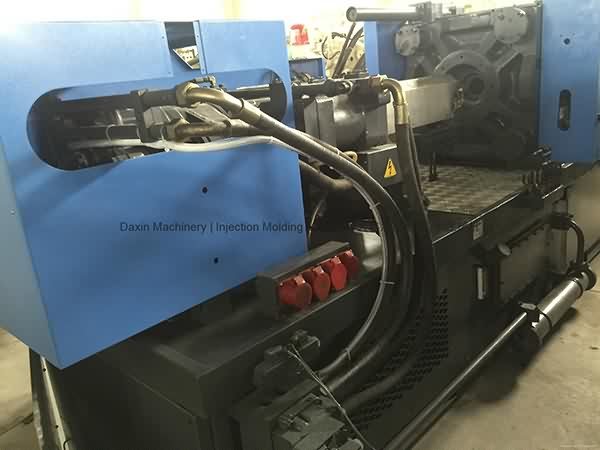

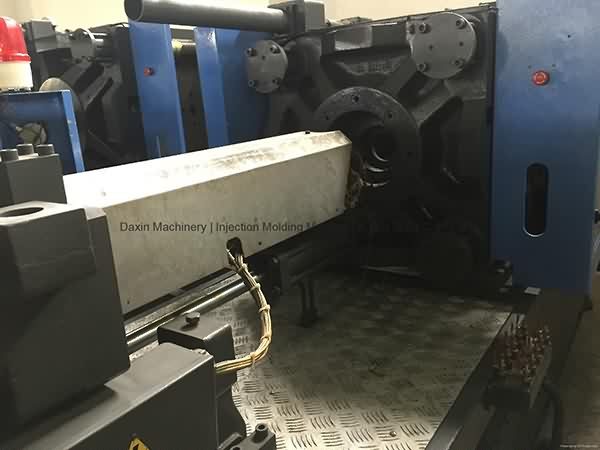

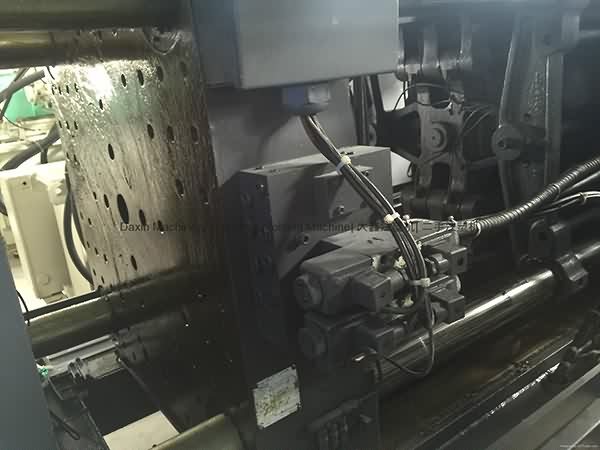

Haitian 200t used injection molding machine.

Youtube Video: https://youtu.be/9icUR6v9ilQ

Model: HTF200W2.

Year: 2006.

Screw diameter: 55/50mm.

Tie bar spacing: 520x520mm.

Two units for sale. Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

www.daxin88.com

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Renewable Design for Haitian HTF200W2 used Injection Molding Machine to kazan Importers, The product will supply to all over the world, such as: South Korea , Durban , Romania , Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

Gelong industries

www.gelongindustries.com

Manufactures & Traders of-DALL, BESAN, FLOUR MILL MACHINERY.

A 15 vikas vihar, chander vihar, nilothi ext. Part 3. New Delhi

Mobile number 09911401311, 09868241884, 8800341233

For videos type (gelong.in)in YouTube

Email address :- gelongindustries@gmail.com

small besan plant

raw material for besan plant

mini besan plant project report

besan plant video

mini besan mill project report

besan pulverizer

rajdhani besan plant

besan manufacturers in indore

besan manufacturing process

price of besan per kg

besan wholesale price

besan mill plant cost

rajdhani besan 1kg price

dal mill plant in india

dal mill process

dal mill business

rice mill

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.