Renewable Design for JSWJ1600EIII used Injection Molding Machine for Mecca Manufacturer

Renewable Design for JSWJ1600EIII used Injection Molding Machine for Mecca Manufacturer Detail:

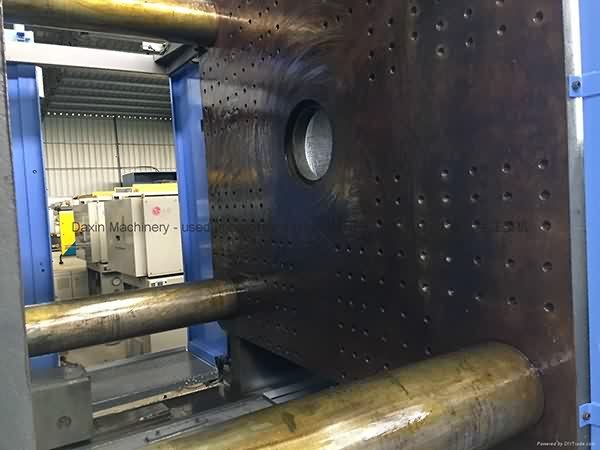

JSW 1600t used injection molding machine.

Model: J1600EIII.

Year: 2008.

Tie bar spacing: 1530x1280mm.

Screw diameter: 140mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Renewable Design for JSWJ1600EIII used Injection Molding Machine for Mecca Manufacturer, The product will supply to all over the world, such as: Turin , Sydney , Slovenia , With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we've been striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

related video: https://www.youtube.com/watch?v=y9HS9sb22Mw

contact us by

support@cnheattransfer.cn / chloe@asia-print.com

Whatsapp / Tel: +86-13728059112

SUPPORT FREE ENERGY USE THIS LINK# seo MUST SEE VIDEOS TOP 12 free energy https://www.gofundme.com/hutchison-effect-energy i upload videos ...

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!