Renewable Design for Niigata 180t used All-electric Injection Molding Machine to Jeddah Factory

Renewable Design for Niigata 180t used All-electric Injection Molding Machine to Jeddah Factory Detail:

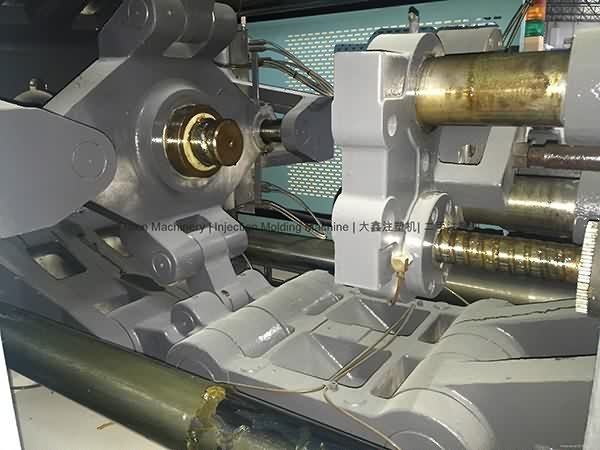

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Renewable Design for Niigata 180t used All-electric Injection Molding Machine to Jeddah Factory, The product will supply to all over the world, such as: Lahore , Uzbekistan , Myanmar , We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

Check details of thin wall products injection molding machines: https://www.powerjet-machinery.com/high-speed-thin-wall-injection-molding-machine/ Any ...

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.