Renewable Design for Niigata 450t All-electric used Injection Molding Machine to Slovak Republic Importers

Renewable Design for Niigata 450t All-electric used Injection Molding Machine to Slovak Republic Importers Detail:

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

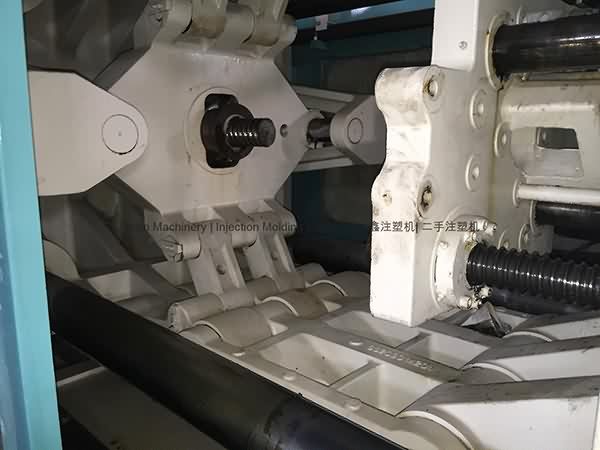

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Renewable Design for Niigata 450t All-electric used Injection Molding Machine to Slovak Republic Importers, The product will supply to all over the world, such as: Israel , Lyon , Latvia , We are proud to supply our products and solutions to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

This video was uploaded from an Android phone.

My first time in China. I was enlightened to see this.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!