Short Lead Time for CLF-200TY used Injection Molding Machines for Cyprus Manufacturers

Short Lead Time for CLF-200TY used Injection Molding Machines for Cyprus Manufacturers Detail:

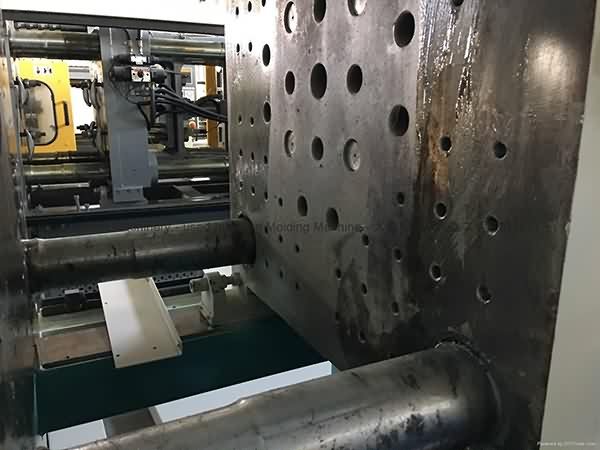

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Short Lead Time for CLF-200TY used Injection Molding Machines for Cyprus Manufacturers, The product will supply to all over the world, such as: Czech , Paraguay , Albania , Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

Visit "www.downloadshiva.com" for more Movies, videos & Documentries. Please Subscribe to the Channel if you like the post.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.