Short Lead Time for Haitian 160t used Injection Molding Machine to Slovenia Factories

Short Lead Time for Haitian 160t used Injection Molding Machine to Slovenia Factories Detail:

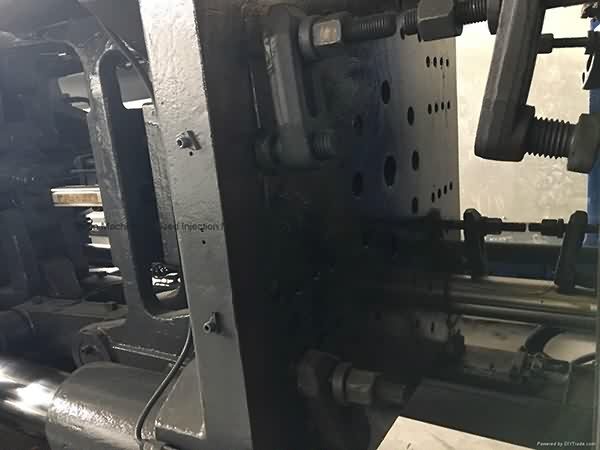

Haitian 160t used plastic injection molding machine.

Model: SA1600/540v.

Year: 2006.

Tie bar spacing: 465x465mm.

Screw diameter: 38mm.

Screw type: B-D38.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Short Lead Time for Haitian 160t used Injection Molding Machine to Slovenia Factories, The product will supply to all over the world, such as: belarus , Holland , Swansea , Our company always concentrate on the development of the international market. We've got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Orthotic insoles are shoe inserts that have been specially designed to relieve biomechanical stresses by helping to restore the natural position of the foot.

DKM turnkey project company always help customer choose the most suitable injection molding machine and auxiliary machines. we have around 30 engineers ...

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.