Short Lead Time for Haitian 200t (servo) used Injection Molding Machine for Vancouver Factory

Short Lead Time for Haitian 200t (servo) used Injection Molding Machine for Vancouver Factory Detail:

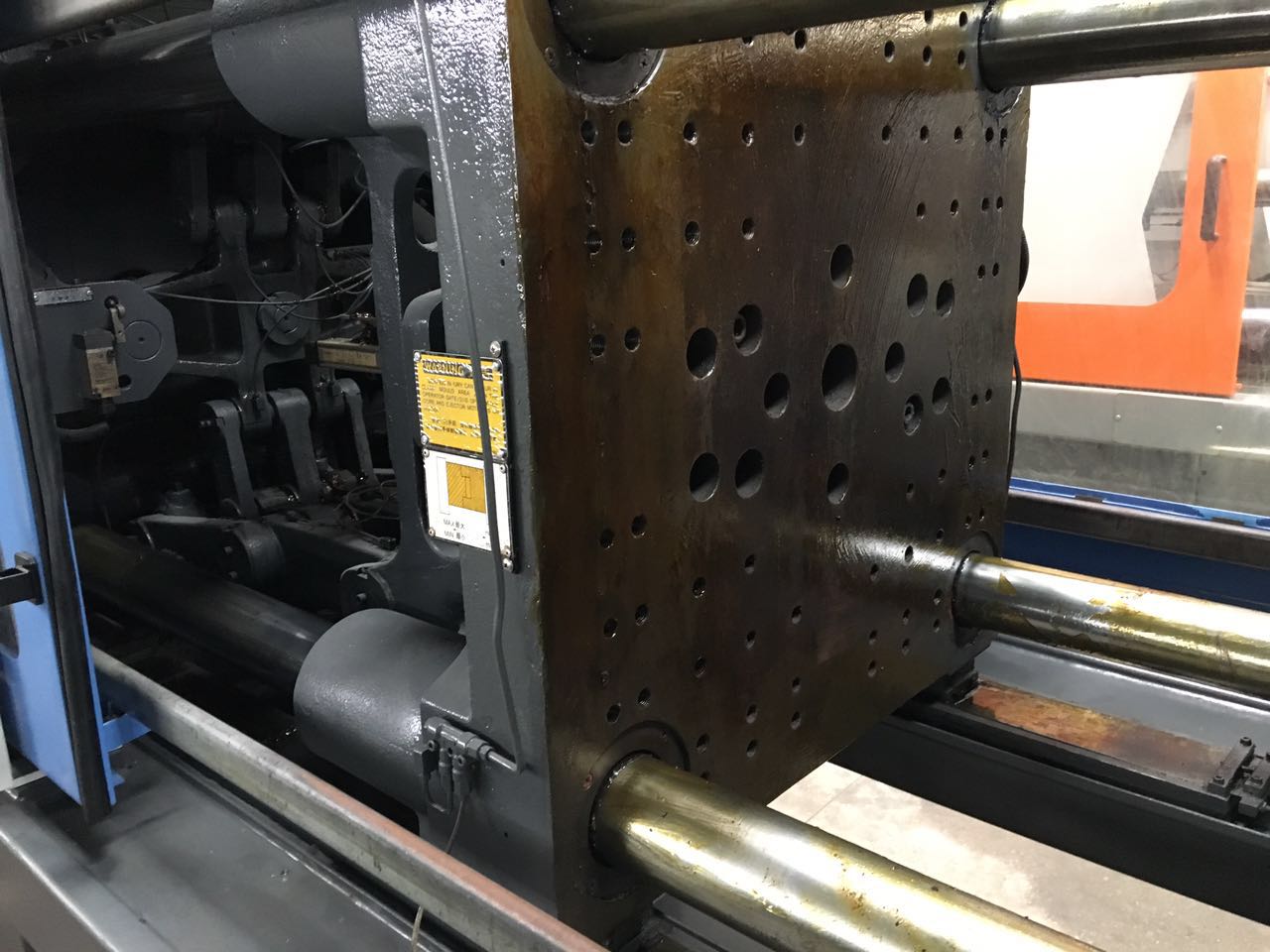

Haitian 200t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for Short Lead Time for Haitian 200t (servo) used Injection Molding Machine for Vancouver Factory, The product will supply to all over the world, such as: Accra , Detroit , luzern , Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

Blow molding machine for plastic panel

Good quality and best price can make your needs

It is a special machines used for producing products with High Molecular Weight High Density

Polyethylene (HMWHDPE) as the raw material, including oversize plastic wall panels,door panels,ocean buoys,safety barriers for highway,athletic equipments,and plastic products of recreational facilities.The machines is designed and manufactured in accordance with standards of similar machine models of Germany,and this machine model has the optimized performance price ratio in the world.

TDB160E is an accumulation and injection type extrusion blow molding machine which can produce plastic door panels and plastic desktop panels.It has reasonable structure and steady and reliable performance.

Neck up, always neck up, avoid any problem in the whole process.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.