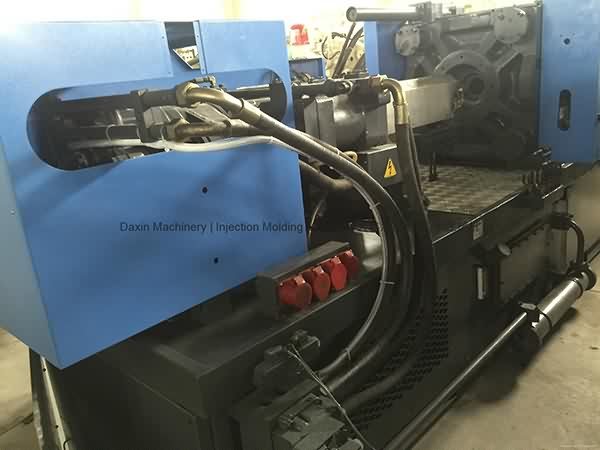

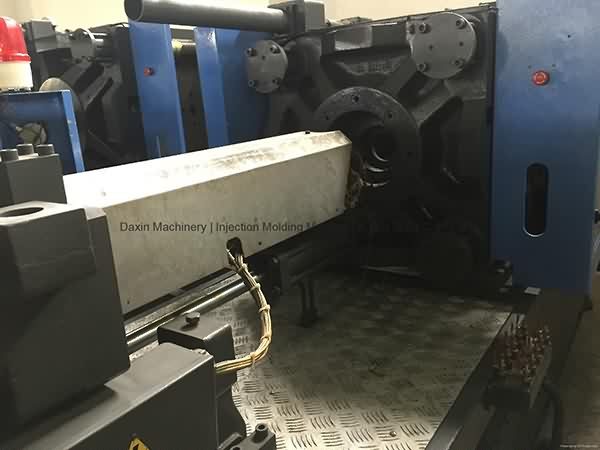

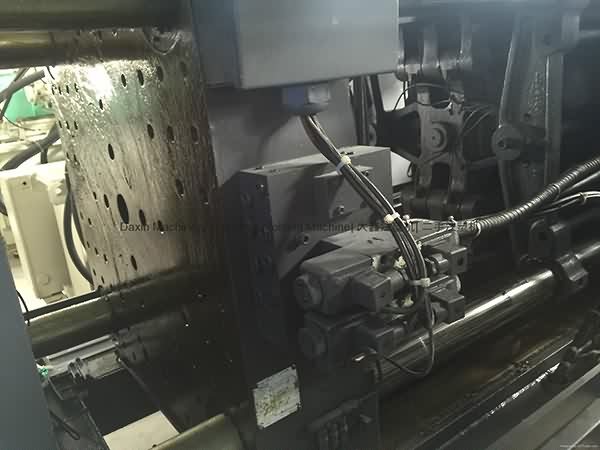

Short Lead Time for Haitian HTF200W2 used Injection Molding Machine for Boston Factories

Short Lead Time for Haitian HTF200W2 used Injection Molding Machine for Boston Factories Detail:

Haitian 200t used injection molding machine.

Youtube Video: https://youtu.be/9icUR6v9ilQ

Model: HTF200W2.

Year: 2006.

Screw diameter: 55/50mm.

Tie bar spacing: 520x520mm.

Two units for sale. Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

www.daxin88.com

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for Short Lead Time for Haitian HTF200W2 used Injection Molding Machine for Boston Factories, The product will supply to all over the world, such as: Madras , Saudi Arabia , Puerto Rico , Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

We manufacture dual color injection unit,injection machine and moulds by ourself. Sino holdings group is a powerful company with 7 branch companies.

This is our plastic injection molding object handling robot. The robot is servo driven and is Euromap12 compatible. This robot is Made in Iran by Mexima ...

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!