Short Lead Time for Sumitomo 130t All-Electric used Injection Molding Machine for Philippines Manufacturers

Short Lead Time for Sumitomo 130t All-Electric used Injection Molding Machine for Philippines Manufacturers Detail:

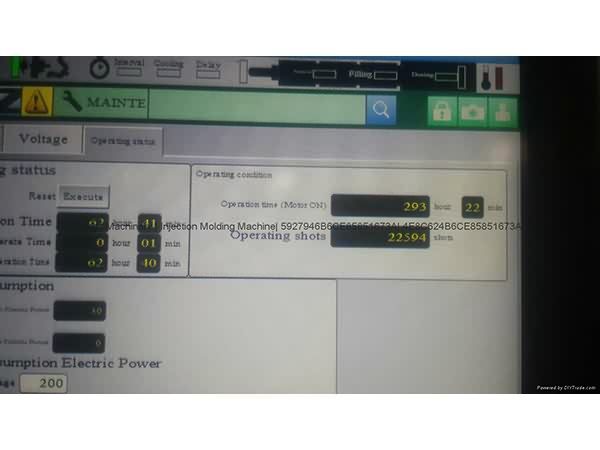

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Short Lead Time for Sumitomo 130t All-Electric used Injection Molding Machine for Philippines Manufacturers, The product will supply to all over the world, such as: The Swiss , Sierra Leone , Hongkong , We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

Mold-Masters Melt-CUBE Direct Side Gating Hot Runner System with TIM-Plastik Mold for Medical Injection Molding of a 20ml Syringe Barrel with Luer Lock -- as see live at ARBURG Technology Days in Loßburg, Germany (March 13-16, 2013)

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.