Short Lead Time for Toshiba 1300t (wide platen) used Injection Molding Machine – Plastic Equipment

Short Lead Time for Toshiba 1300t (wide platen) used Injection Molding Machine – Plastic Equipment Detail:

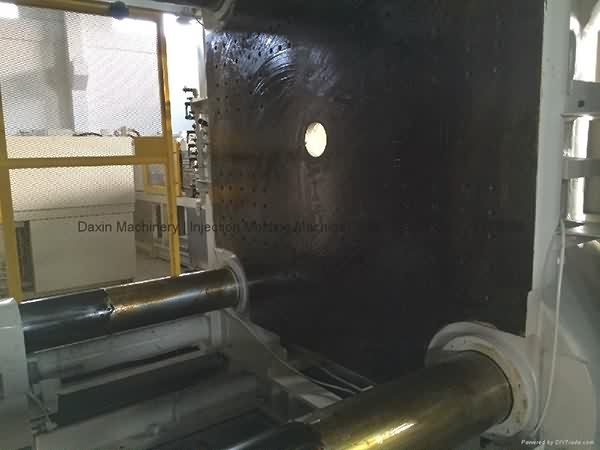

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for Short Lead Time for Toshiba 1300t (wide platen) used Injection Molding Machine – Plastic Equipment, The product will supply to all over the world, such as: Tunisia , Albania , Greece , Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

plastic reprocessing plant Mumbai, model EP 100

Original manufacturer of Plastic recycling machinery India

Send inquiry for plastic reprocessing plant Mumbai to: europack1@gmail.com

Find more information on plastic reprocessing plant India on: europack1@gmail.com

Europack Machines is a professional plastic reprocessing plant manufacturer in India, we design and manufacture Plastic recycling machinery India based on your requirement. We produce a wide range of Plastic recycling machinery India, including die face cutting, water ring pelletizer, under-water pelletizer, spaghetti (noodle type) pelletizer...

The main feature of Model plastic reprocessing plant India is shredder integrated.

EUROPACK manufactures Plastic recycling machinery India with higher and lower capacity available from 80~900 kg/hr.

Plastic recycling machinery produces high quality pellets. The produced pellets from Plastic recycling machinery can be put directly back to the production line.

High efficiency machine de recyclage du plastique for post-industrial packaging film, with shredder integrated which eliminates the need to pre-cut material.

machine de recyclage du plastique is very suitable for recycling material PE(HDPE and LDPE) and PP.

Plastic recycling machinery is a perfect equipment for blown film factories to recycle its own in-house waste.

plastic reprocessing plant is very suitable for recycling material PE(HDPE and LDPE) and PP.

plastic reprocessing plant is a perfect equipment for blown film factories to recycle its own in-house waste.

Applicable material for Plastic recycling machinery :

HDPE film

LDPE film

PP waste bag

HDPE edge trim waste

LDPE edge trim waste

T-shirt bag cut off

PP raffia

Foam

PE sheet

PE Flake

Complete film roll

This video was uploaded from an Android phone.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!