Special Design for Chen Hsong Super Master SM50 used Injection Molding Machine for Toronto Manufacturers

Special Design for Chen Hsong Super Master SM50 used Injection Molding Machine for Toronto Manufacturers Detail:

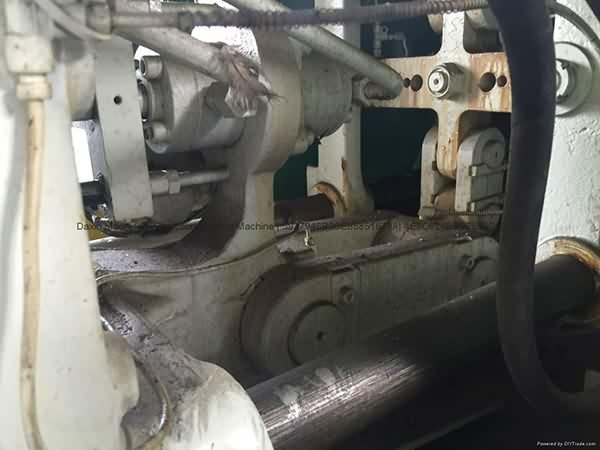

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Special Design for Chen Hsong Super Master SM50 used Injection Molding Machine for Toronto Manufacturers, The product will supply to all over the world, such as: Turkey , Denver , Hanover , Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Manual Spacer Bar Round Curve Bender,Manual Spacer Bar Round Bender,Spacer Bar Curve Bending Machine,Spacer Bar Curve Bender,Aluminum Spacer Bar Curve Bending Machine,Aluminum Spacer Bar Curve Bender,Spacer Bar Round Bender,Spacer Bar Round Bending Machine,Aluminum Spacer Bar Bender,Aluminum Spacer Bar Bending Machine,Manual Spacer Bar Round Bender,Semi-Automatic Spacer Bar Round Bender,Manual Spacer Bar Round Bending Machine,Manual Aluminum Spacer Bar Bender,Manual Aluminum Spacer Bar Bending Machine,Semi-Automatic Spacer Bar Round Bending Machine,Semi-Automatic Aluminum Spacer Bar Bender,Semi-Automatic Aluminum Spacer Bar Bending Machine,Manual Spacer Bar Curve Bending Machine,Manual Spacer Bar Curve Bender,Manual Aluminum Spacer Bar Curve Bending Machine,Manual Aluminum Spacer Bar Curve Bender,Manual Spacer Bar Curve Bending Machine,Semi-Automatic Spacer Bar Curve Bender,Semi-Automatic Aluminum Spacer Bar Curve Bending Machine,Semi-Automatic Aluminum Spacer Bar Curve Bender,Semi-Automatic Spacer Bar Curve Bending Machine,Semi-Automatic Spacer Bar Curve Bender,Semi-Automatic Aluminum Spacer Bar Curve Bending Machine,Semi-Automatic Aluminum Spacer Bar Curve Bender

If any interested in it,pls send emails to sales@saintbestgroup.com or saintbestgroup@163.com or add Skype:allenszj for direct conversation.

URL:www.saintbestgroup.com www.doubleglazingequipment.com www.digitaluvprinter.com www.shuntaitech.com

Whatsapp/Wechat:+86-186-6042-5078

We manufacture Extruder Screws, Injection Molding Screws, Twin Screws and Rubber Screws used in the plastic, rubber industry's for more than 15 years.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.