Special Design for Chen Hsong Super Master SM50 used Injection Molding Machine Supply to Islamabad

Special Design for Chen Hsong Super Master SM50 used Injection Molding Machine Supply to Islamabad Detail:

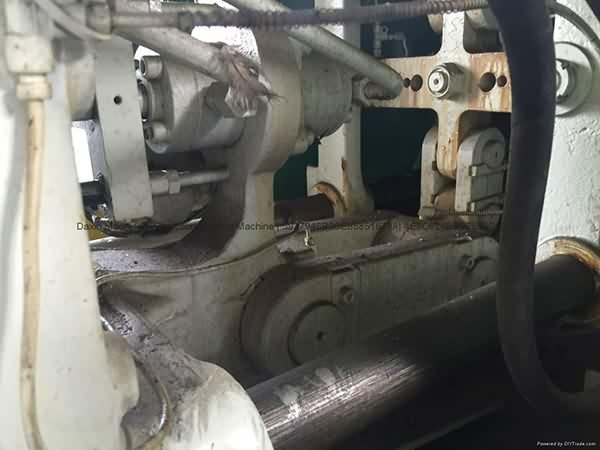

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for Special Design for Chen Hsong Super Master SM50 used Injection Molding Machine Supply to Islamabad, The product will supply to all over the world, such as: Mexico , UAE , Myanmar , Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

Blow molding machine for plastic panel

Good quality and best price can make your needs

It is a special machines used for producing products with High Molecular Weight High Density

Polyethylene (HMWHDPE) as the raw material, including oversize plastic wall panels,door panels,ocean buoys,safety barriers for highway,athletic equipments,and plastic products of recreational facilities.The machines is designed and manufactured in accordance with standards of similar machine models of Germany,and this machine model has the optimized performance price ratio in the world.

TDB160E is an accumulation and injection type extrusion blow molding machine which can produce plastic door panels and plastic desktop panels.It has reasonable structure and steady and reliable performance.

To contact the seller and view more details, visit https://www.listatool.com/listings/victor-uh-1-horiz-vertical-combination-miller

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.