Special Design for CLF-1000T (servo) used Injection Molding Machine for Buenos Aires Factories

Special Design for CLF-1000T (servo) used Injection Molding Machine for Buenos Aires Factories Detail:

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

Product Image

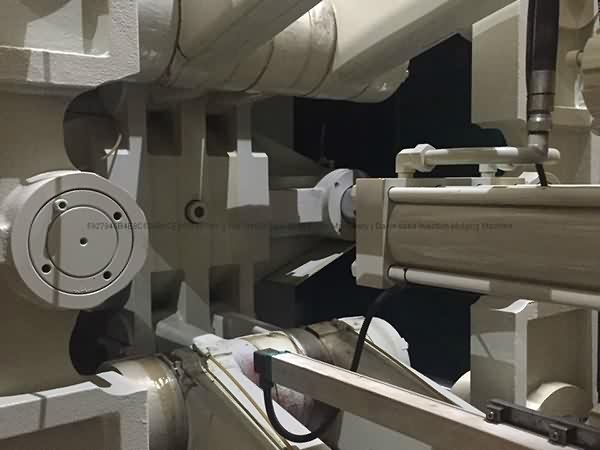

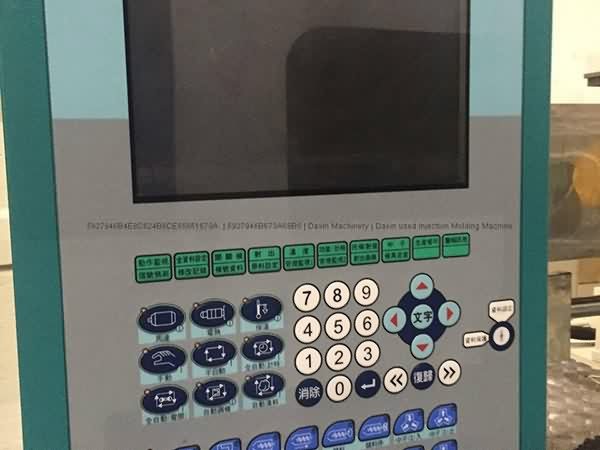

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Special Design for CLF-1000T (servo) used Injection Molding Machine for Buenos Aires Factories, The product will supply to all over the world, such as: Philippines , Colombia , Jordan , Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

Email:info@trumarkindia.com

whatsapp/ viber/ hike mobile:+919870789174

www.trumarkindia.com

skype: trumarkharma

table top coding machine to print Batch No.., Mfg. Date., Exp. Date., Retail Price etc.. on their plain or laminated & varnished Labels/Cartons, Polypack Bags, Pouches, bottles, jar, boxes or any solid objects etc.Ease of use & maintenance free features makes it very useful for medium scale industries which have daily production of up to 5000-10000 prints.It uses very fast drying liquid ink which is suitable for laminated, varnished, UV coated, metallic, porous, nonporous surface also & available in different colors.It can print on any flat or slightly curved solid surface.

semi automatic emc 35x35 coding machine is electro mechanical batch machine coding system which can adopt to print many method, it can be mounted on online ffs machine to print on pouch roll, al foil etc on blister machine, can be mounted on conveyor to print on boxes, jar, containers.

also available in pneumatic models & other sizes

batch coding machine for pouch, how to print mark code mrp, batch number code , date of manufacturing, expiry date on round bottle, jar, carton, labels, leaflets, outer box, flat oval shape bottle, plastic moulded parts, metal spare parts, frames, rubber sheet, plywood, sanitary items, pvc sheet, bucket, paint tin, tin can,

for all above application our batch coder, batch printer, semi auto coding printing marking machine is best suitable.

manufacturer from mumbai india, supplier, distributor, seller, exporter from India in USA, France, Poland, Bulgaria, Saudi Arabia, Ecuador, Peru, South Africa, Egypt, Indonesia, UAE, Vietnam, Pakistan, Uganda, Philippines, Greece, Columbia, Malaysia, Nigeria, Ethiopia, Lebanon, Kenya, Kuwait, Sri Lanka, Ghana, Nepal, Ukraine, Bangladesh, Australia, Switzerland, Sudan, Russia, Yemen, Iran, Morocco, Malawi, Thailand, Tanzania, Canada, Belarus ,USA ,Cyprus ,UAE ,Republic of Congo ,Canada ,Russia ,South Africa ,Crotia ,Nepal ,OMAN ,UKRAINE ,China ,Bhutan ,Ghana ,Yugoslavia ,Nigeria ,Netherlands ,Vietnam ,Thailand ,Kenya ,Iran ,Malaysia ,Bangladesh ,Pakistan, U.A.E , SAUDI ARABIA , Monrovia , Phillipines , Spain ,Liberia , Iran ,U.S.A, Canada, Germany, Italy, Jordan, Syria, Turkey, Kuwait, Iran, Algeria, Argentina, Bangladesh, Bangkok, Indonesia, Malaysia, Vietnam, Nigeria, Ghana, Malawi, Egypt, Ukraine, Nepal, Srilanka, Bangladesh, Tibet Lusaka, Egypt, England, UAE, Bahrain, Vietnam, Iran, Poland, Tanzania, Malaysia, Nigeria, Sudan, U.K., Italy, Thailand, Span, Kenya, Lebanon, Kingdom of Saudi Arabia, Sudan, Botswana, Iraq, Thailand, Span, Mauritius, Ethopia, Congo, Zambia, Namibia, Mozambique, Uganda, Yemen, Somaliya, Oman, Jordan, Turkey, Labia, Morocco, France, Germany, Ukraine, Turkey, Greece, Kazakhstan, Russia, Uzbekistan, Malaysia, Thailand,Singapore, Philipines, Indonesia, Australlia, New Zealand etc.

SOLD MACHINE

Injection stretch blow moulding machines for PET bottles second hand Brand: NISSEI ASB Model: PF 8-4B Year: 1999

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300028168?OpenDocument&ln=en&origin=YouTube

Máquina de inyección-soplado para botellas de PET segunda mano Marca: NISSEI ASB Modelo: PF 8-4B Año: 1999

Spritzblasformmaschine Gebrauchtmaschinen,

Souffleuse d'injection Machine d'occasion,

Soffiatrice di iniezione soffiaggio per bottiglie di PET macchina di seconda mano,

бывшее в употреблении оборудование,

Maszyny do produkcji preformy z wydmuchaniem butelki maszyny z drugiej reki,

Enjeksiyon streç şişirme kalıplama makinesi

--Enjeksiyon şişirme makinası

Kullanılmış makine,

Injekció strech flakonfúvó gépek PET-palackok Használt gép,

Vstřikovací protáhnout vyfukovací stroje na PET láhve Použitý Stroj

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.