Special Design for Niigata 180t used All-electric Injection Molding Machine for Adelaide Importers

Special Design for Niigata 180t used All-electric Injection Molding Machine for Adelaide Importers Detail:

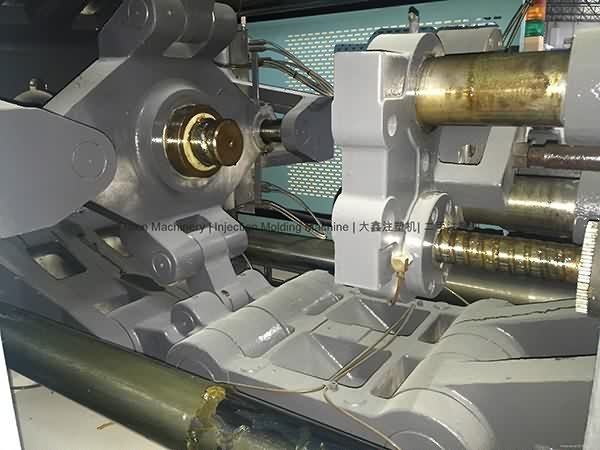

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for Special Design for Niigata 180t used All-electric Injection Molding Machine for Adelaide Importers, The product will supply to all over the world, such as: Germany , Estonia , belarus , The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

Water Damage Restoration? North Lindenhurst, NY Call (631) 888-6080 24/7, Call Now (613) 888-6080, or look at our website for more information. 24 Hours 365 Days Per Year

https://westbabylonrestorationpros.com/

Contact: Ms Linda Liu

MP:+86-18865650128

Email:gbllinda@hotmail.com

SKYPE: linda-82132006

QQ: 20579250

https://www.foam-container-machine.com

PS foam sheet extruder machine/PS foam sheet plastic extruder

PS/EPS fully auto forming and cutting machine can form PS/EPS foam box, tray, plate, container, egg box etc. by changing moulds. We will design mould according to your sample and requirements, and can also put your company LOGO on the mould. It is fully automatic. Forming, cutting and stacking are done in the same machine.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!