Special Design for Niigata 450t All-electric used Injection Molding Machine for United Arab Emirates Manufacturers

Special Design for Niigata 450t All-electric used Injection Molding Machine for United Arab Emirates Manufacturers Detail:

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

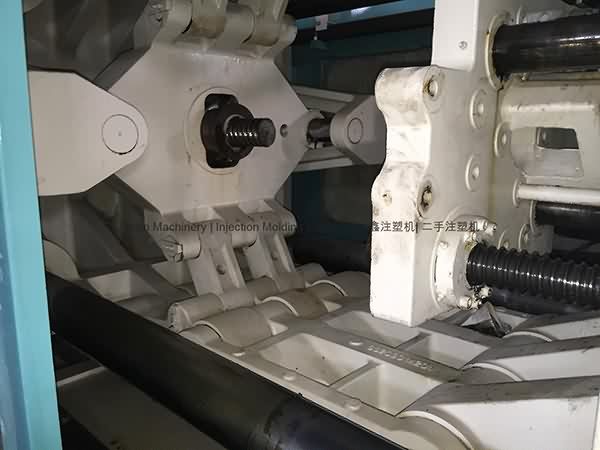

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Special Design for Niigata 450t All-electric used Injection Molding Machine for United Arab Emirates Manufacturers, The product will supply to all over the world, such as: Costa Rica , Uzbekistan , Philippines , What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

Any questions,feel free to contact me. Email:htpmachinery@gmail.com Skype:zhang.tracy6 More information:https://twitter.com/htpmachinery Chick here to ...

Techspan New Zealand have represnted ENGEL since 1979 -

In this video - ENGEL easix - the multifunctional 6-axis robot

Working with ease in all three dimensions: The ENGEL easix six-axis robot and its integrated control unit are ideally equipped for current and future tasks, making your production even more efficient. No matter whether you need a particularly flexible automation solution or face special requirements, such as cleanroom production.

Further information: https://www.techspan.co.nz/engel/

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.