Special Price for CLF-200TY used Injection Molding Machines for New Zealand Factory

Special Price for CLF-200TY used Injection Molding Machines for New Zealand Factory Detail:

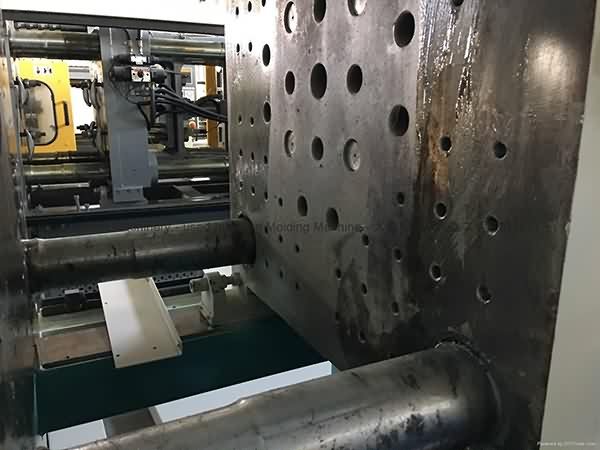

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Special Price for CLF-200TY used Injection Molding Machines for New Zealand Factory, The product will supply to all over the world, such as: Ukraine , Lisbon , Portugal , Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

https://www.auctionmasters.com

Auction Masters is your online resource for bidding on and selling commercial inventory in Minnesota. We efficiently manage every component of online auctions. Get started today!

Superfast injection molding of LSR (liquid silicon rubber) with a hybrid ENGEL e-victory 130 US and 64 cavities mold from ACH Solution.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!