Special Price for JSWJ1300EIII used Injection Molding Machine to Lithuania Factories

Special Price for JSWJ1300EIII used Injection Molding Machine to Lithuania Factories Detail:

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

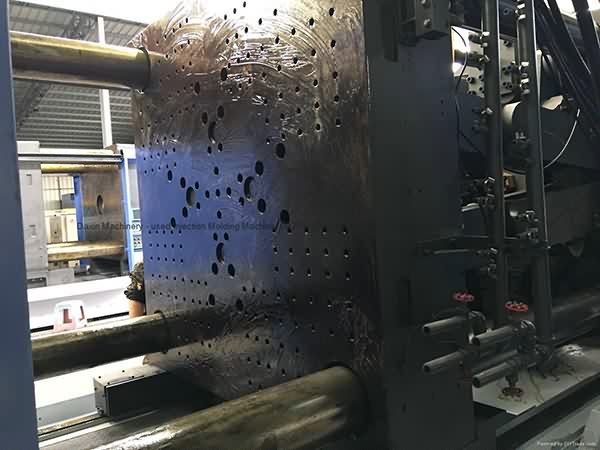

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for Special Price for JSWJ1300EIII used Injection Molding Machine to Lithuania Factories, The product will supply to all over the world, such as: Kenya , Hungary , Ghana , We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

Laser engraving stainless steel, brass, aluminum (iPhone, iPad ), iron, gold, silver, titanium and metal,laser engraving plastic, marble, ceremic etc. China industrial fiber laser engraving machine manufacturer. Desktop laser engraving machine for metal laser engraving and plastics marking. Laser engraving logo, text, QR code, bar code, serial number. Looking for distribuotrs and users all over the world.

https://laser-engraving-machine.com

https://toplasertech.com

https://prolasertech.com

Industrial Laser Engraving Application:

Electronic Components: Resistors, Capacitors, Chips, Printed Circuit Boards, Computer Keyboard, etc.

Mechanical Parts: Bearing, Gears, Standard Parts, Motor, etc.

Instrument: Panel Board, Nameplates, Precision equipment, etc.

Hardware Tools: Knives, Tools, Measuring Tools, Cutting Tools, etc.

Automobile Parts: Pistons and Rings, Gears, Shafts, Bearings, Clutch, Lights, etc.

Daily Necessities: Handicrafts, Zipper, Key Holder, Sanitary Ware, etc.

TopLaserTech Laser Engraving System manufactures a full range of CO2 and Fiber laser marking machine, laser engraving machine and laser cutting machine powered by world-leading laser brands such as IPG, SPI, Synrad, Coherent, GSI and RECI.

TopLaserTech Laser Machines bring you new concepts of industrial fiber laser engraving machine and laser marking machine, CO2 laser engraving machine and laser cutting machine - proudly designed and built right here in China.

If you are interested in our laser engraving machines, welcome to contact us for prices, videos, specifications and more. Looking for distributors and users all over the world.

***********************************************************

TopLaserTech

leo@toplasertech.com

skype: service@toplasertech.com

mobile/whatsapp/viber/Wechat: +86-18672776295

https://laser-engraving-machine.com

https://toplasertech.com

https://prolasertech.com

A new hybrid 3D printing technique developed at the Wyss Institute at Harvard University, Harvard’s John A. Paulson School of Engineering and Applied Sciences, and the Air Force Research Laboratory combines stretchable conductive inks and electronic components into flexible, durable wearable devices that move with the body and offer increased programmability. Credit: Wyss Institute at Harvard University

To learn more, please visit: https://wyss.harvard.edu/low-cost-wearables-manufactured-by-hybrid-3d-printing

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!