Super Purchasing for Chen Hsong Super Master SM450TS used Injection Molding Machine Export to Bangladesh

Super Purchasing for Chen Hsong Super Master SM450TS used Injection Molding Machine Export to Bangladesh Detail:

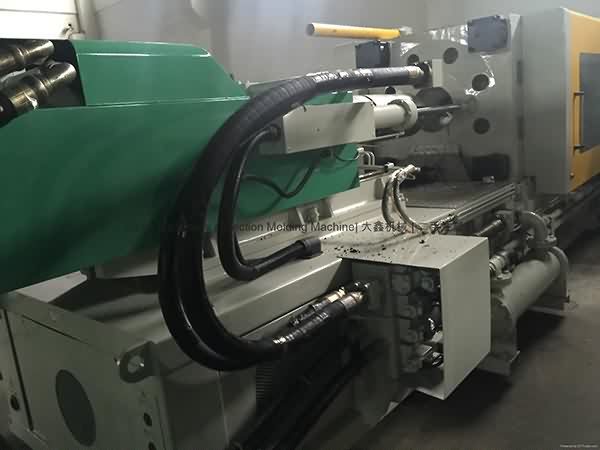

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Super Purchasing for Chen Hsong Super Master SM450TS used Injection Molding Machine Export to Bangladesh, The product will supply to all over the world, such as: Porto , Belarus , Philadelphia , "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

rubber transfer molding press

rubber injection type rubber molding press

Hydromech rubber transfer molding press

WE PROVIDE ALL KINDS OF PRODUCTS FOR SHOES PRODUCTION - MACHINE / MOULDS / MATERIALS / TURN KEY PRODUCTS . please contact ...

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.