Super Purchasing for JSWJ1600EIII used Injection Molding Machine Wholesale to Seattle

Super Purchasing for JSWJ1600EIII used Injection Molding Machine Wholesale to Seattle Detail:

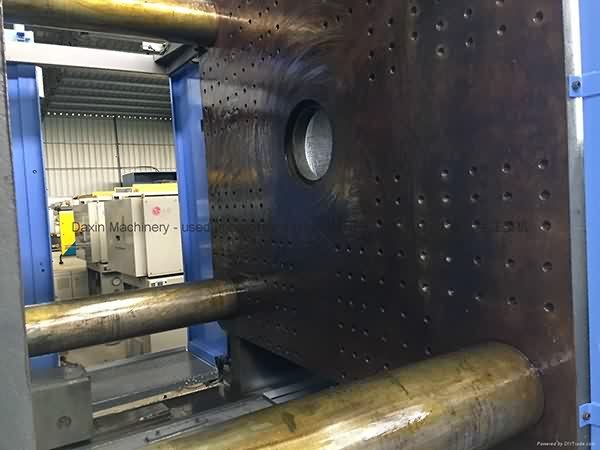

JSW 1600t used injection molding machine.

Model: J1600EIII.

Year: 2008.

Tie bar spacing: 1530x1280mm.

Screw diameter: 140mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

Our goal is to satisfy our customers by offering golden service, good price and high quality for Super Purchasing for JSWJ1600EIII used Injection Molding Machine Wholesale to Seattle, The product will supply to all over the world, such as: Portugal , Vietnam , Lebanon , Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Any questions,feel free to contact me. Email:htpmachinery@gmail.com Skype:zhang.tracy6 More information:https://twitter.com/htpmachinery Chick here to ...

Used Rajoo PP Film Machine. Plastic Film Extruder For Sale In Karnataka

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!