Super Purchasing for Mitsubishi 1300t Used Injection Molding Machine to Brasilia Importers

Super Purchasing for Mitsubishi 1300t Used Injection Molding Machine to Brasilia Importers Detail:

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

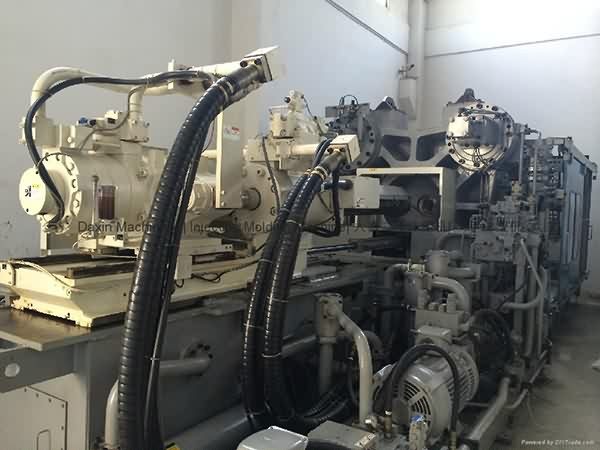

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for Super Purchasing for Mitsubishi 1300t Used Injection Molding Machine to Brasilia Importers, The product will supply to all over the world, such as: Switzerland , Burundi , Israel , Our objective is "to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us". If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

new 2012 rubber boots a brand new vintage 80s rubber boots,

pvc braided hose extrusion machine line weifang jingda plastic machinery co.,

Weifang Jingda Plastic Machinery Co.,Ltd

Add:Changle, Weifang, Shandong, China

https://www.hoseextruder.com

Email: info@hoseextruder.com

Mobile/WhatsApp/Viber: 008615715362527

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!