Top Quality Mitsubishi 1300t Used Injection Molding Machine Wholesale to Canada

Top Quality Mitsubishi 1300t Used Injection Molding Machine Wholesale to Canada Detail:

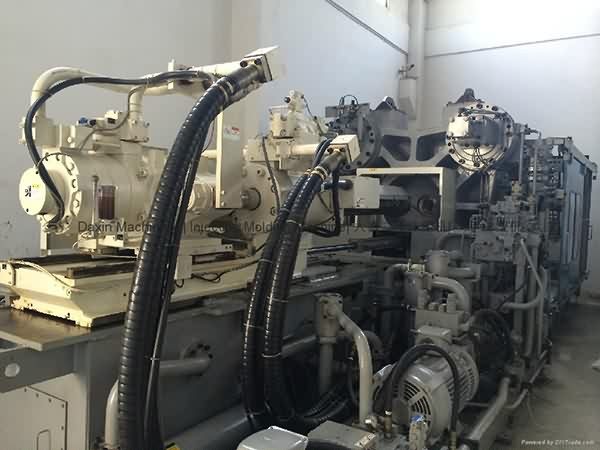

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for Top Quality Mitsubishi 1300t Used Injection Molding Machine Wholesale to Canada, The product will supply to all over the world, such as: Iceland , UK , Bangkok , we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Plastic Injection Molding Machine-SH KC 200M8-SH 2014 export Algeria.

Huaao Electricity Technology Co.,Ltd is the only supplier who professional produce: APG machine,APG molds,casting mold and instrument transformer winding ...

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!