Top Quality Toshiba IS450GS Used Injection Molding Machine for Las Vegas Importers

Top Quality Toshiba IS450GS Used Injection Molding Machine for Las Vegas Importers Detail:

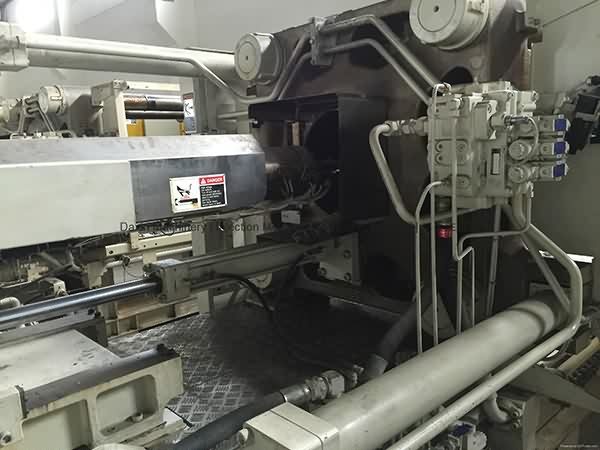

Toshiba 450t used plastic injection molding machine

Youtube: https://youtu.be/WJngGtO1BdI

Model: IS450GS.

Year: 2003.

Screw diameter: 70mm.

Injection weight: 1360g

Tie bar spacing: 810x810mm.

Controller: V10.

A few units for sale. Machines are in good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us after Chinaplas to power on the machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Top Quality Toshiba IS450GS Used Injection Molding Machine for Las Vegas Importers, The product will supply to all over the world, such as: Senegal , Victoria , Wellington , We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

WE ARE THE BEST PLASTIC MACHINE SUPPLIER: PET semi-automatic stretch blow molding machine Automatic stretch blow moulding machine ...

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!