Trending Products Nanrong 120t used Injection Molding Machine for Brisbane Manufacturer

Trending Products Nanrong 120t used Injection Molding Machine for Brisbane Manufacturer Detail:

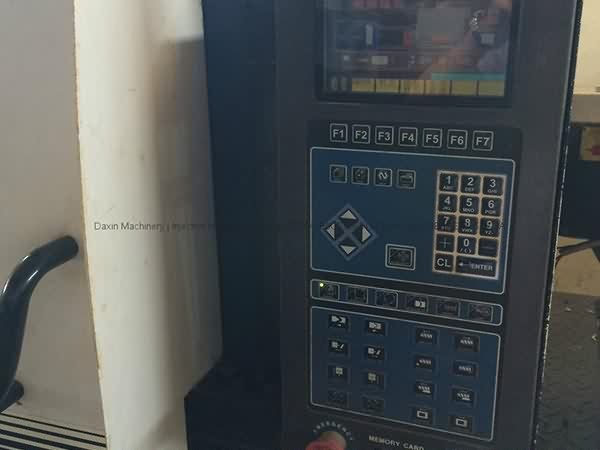

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Trending Products Nanrong 120t used Injection Molding Machine for Brisbane Manufacturer, The product will supply to all over the world, such as: French , Victoria , The Swiss , Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We have achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You will be impressed by our quality and price. Please contact us now!

20,000 Lbs Littell Call 616-200-4308 for more information visit us at https://d1a6prx2duc1gy.cloudfront.net/ or Contact Us at 616-200-4308. Available Equipment changes weekly, call for current updates or get on our email updates list. We also sell & buy machines too.

https://s3-us-west-1.amazonaws.com/affordablemachinery/category/metal-working-machinery/coil-handling-equipment/index.html

https://youtube.com/watch?v=ByvUZTjNusc

MICROTEC ENGINEERING GROUP is engineering company in Australia . It explains corn starch production process . It has many photos showing machinery and equipment for corn starch production. By watching this presentation you would get a general idea of corn starch production process .

For more information you can visit www.microtecco.com

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.