Well-designed CLF-200TY used Injection Molding Machines for Kuala Lumpur Factories

Well-designed CLF-200TY used Injection Molding Machines for Kuala Lumpur Factories Detail:

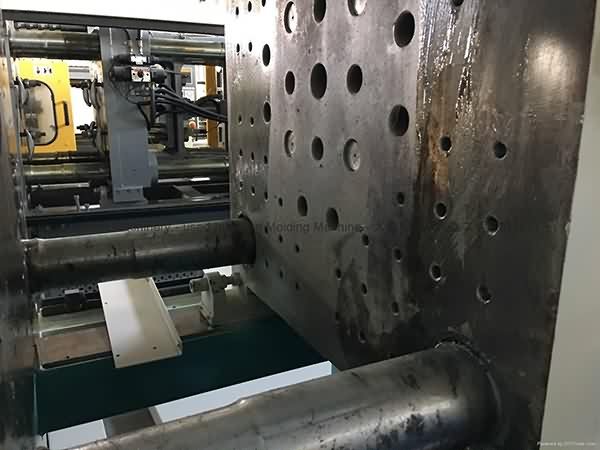

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Well-designed CLF-200TY used Injection Molding Machines for Kuala Lumpur Factories, The product will supply to all over the world, such as: Argentina , Costa rica , Berlin , You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!

Roll forming line for production of Car frame elements

Pay attention: guards and safety barriers have been removed for viewing.

All dispositive must be in place for safe operation

Interlocking Tiles Making Machines and interlocking Tiles Plastic Moulds manufactures in India.

contact us for Concrete Floor Tile mould, Concrete Floor Tile Rubber mould, Designer Floor Tile Plastic mould, Designer Floor Tile PVC mould, Designer Floor Tile Rubber mould, Floor Tile Plastic Mould.

www.srikrishnaplasto.com , info@srikrishnaplasto.com

Precast Concrete pavers making machines and Precast Concrete pavers making process for newly started business.

Plastic mould for interlocking tiles available in different shape and sizes . Interlocking Paver Moulds, Parking tiles moulds, plastic moulds for wet casting, Plastic Paver Moulds, precast paver mould, Rubber Moulds for wet casting, Rubber Paver Moulds.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!