Well-designed Haitian 1300t (servo) used Injection Molding Machine to London Factories

Well-designed Haitian 1300t (servo) used Injection Molding Machine to London Factories Detail:

Haitian 1300t (servo) used Injection Molding Machine for sale.

Model: MA13000/10500

Year: 2012.

Tie bar spacing: 1250mm.

Still running production in factory. Good working condition.

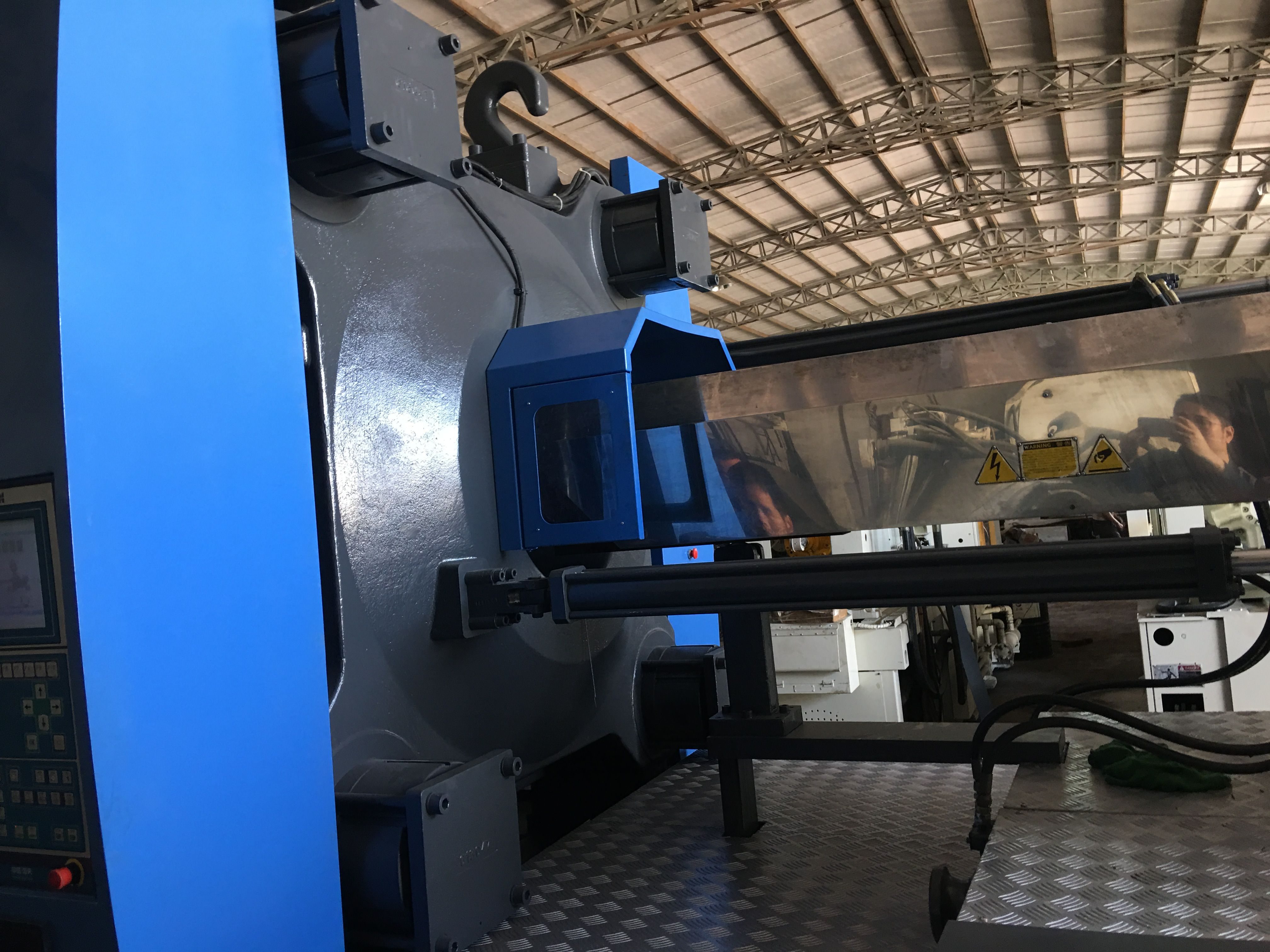

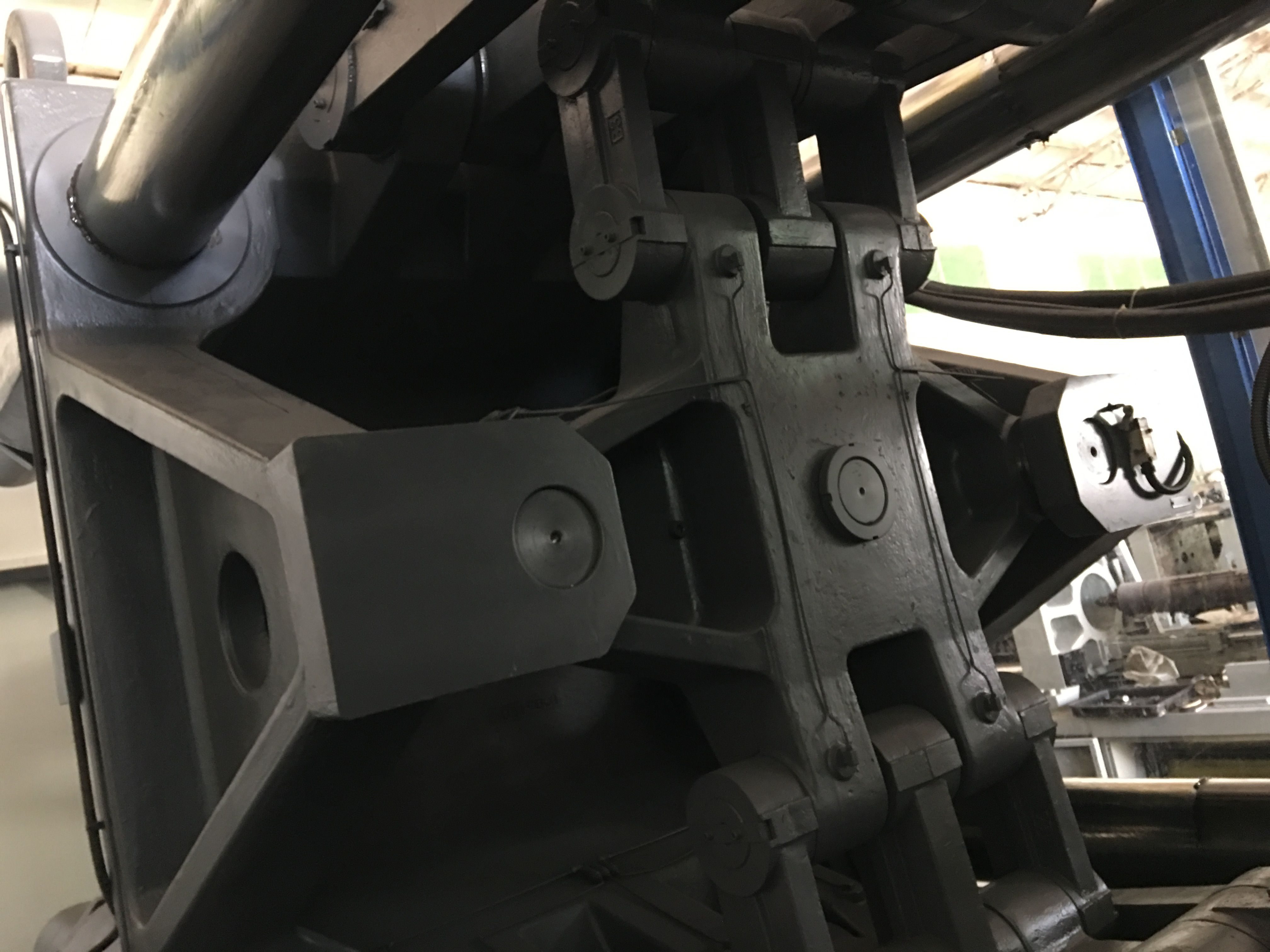

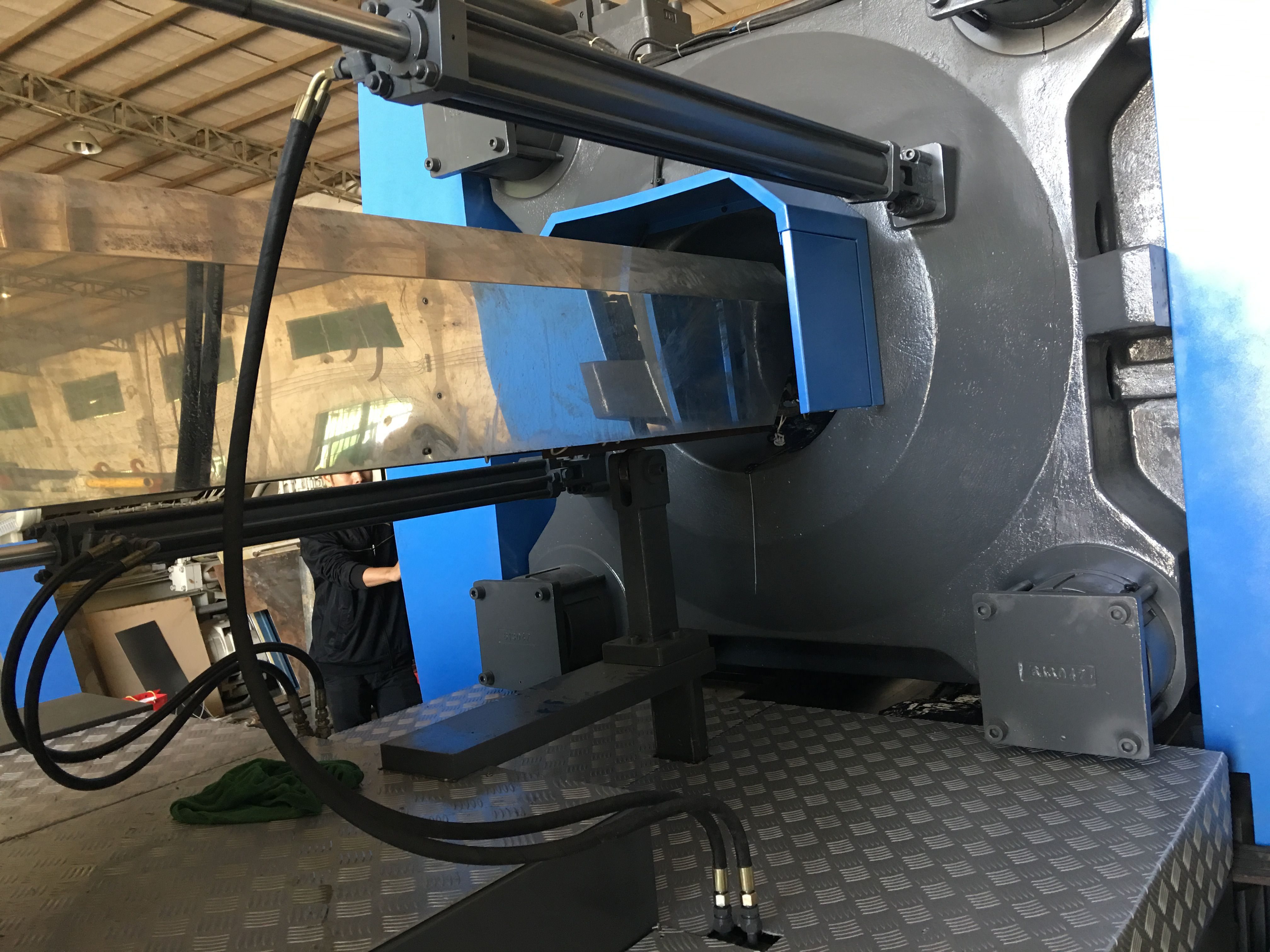

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Well-designed Haitian 1300t (servo) used Injection Molding Machine to London Factories, The product will supply to all over the world, such as: Spain , Orlando , Senegal , Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

Fully-automatic PET Bottle Blow Molding Machine adopt Siemens PLC & Touch Screen,Germany Festo pneumatic system,Japan Mitusbishi Servo Motor ,high ...

cnc moulding machine can engrave on hard metal,wood,acrylic.Moulding machine can engrave different design.besides we have another type moulding ...

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.