Well-designed Hwa Chin 350t double-color used Injection Molding Machine – Electric Used Plastic Injection Molding Machine

Well-designed Hwa Chin 350t double-color used Injection Molding Machine – Electric Used Plastic Injection Molding Machine Detail:

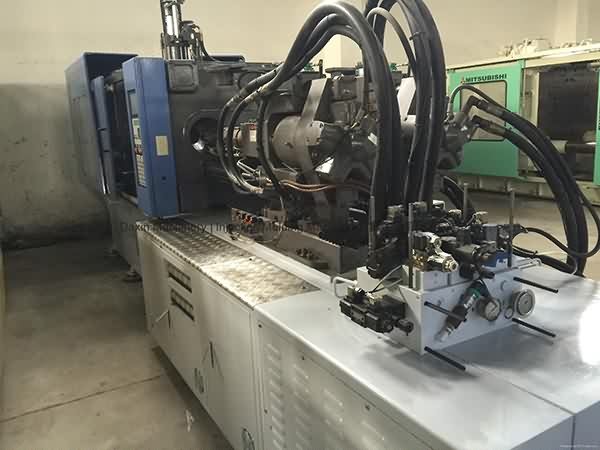

Taiwa Hwa Chin 350t Double Color used Injection Molding Machine.

Model: DC-350.

Year: 2010.

Screw diameters: 32/32mm.

Tie bar spacing: 650x650mm.

Diameter of rotary table: 950mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Well-designed Hwa Chin 350t double-color used Injection Molding Machine – Electric Used Plastic Injection Molding Machine, The product will supply to all over the world, such as: Hungary , Angola , Pretoria , Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

"PP WOVEN BAG" CUTTING & SEWING 90° Servo Transfer Reciprocate Movement Gripper Type

https://www.lungye.com.tw PP WOVEN BAGS 90° CLAW TYPE 2 SERVO MOTOR CUTTING&SEWING MACHINE "Taiwan Machine" 90° Servo Transfer Reciprocate Movement Gripper Type pp woven bag making machine&Printing Machine

20L Pail Forza PT450H Production Dry cycle

Máy ép nhựa Forza 450T ép thùng 20L (máy chạy không tải), với hệ thống dán nhãn bên trong IML, làm cho chu kỳ sản xuất ngắn hơn.

Liên hệ: 0909 725 216

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.