Well-designed Mitsubishi 1300t Used Injection Molding Machine for Turin Importers

Well-designed Mitsubishi 1300t Used Injection Molding Machine for Turin Importers Detail:

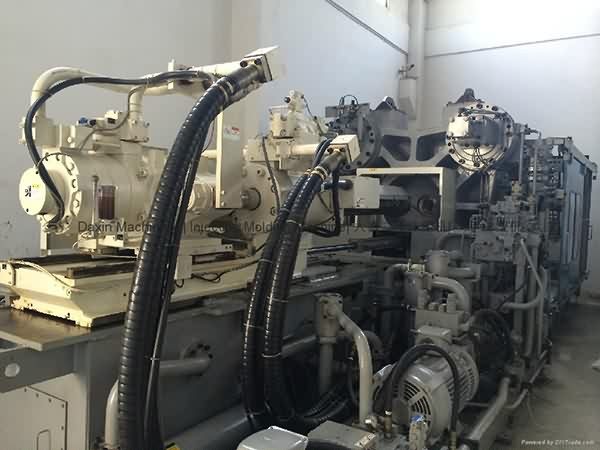

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for Well-designed Mitsubishi 1300t Used Injection Molding Machine for Turin Importers, The product will supply to all over the world, such as: Denmark , Zimbabwe , Lebanon , At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

PU foaming machine for making safety shoes.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!