Wholesale Discount Donghua 320t (variable pump) used Injection Molding Machine for Pretoria Factories

Wholesale Discount Donghua 320t (variable pump) used Injection Molding Machine for Pretoria Factories Detail:

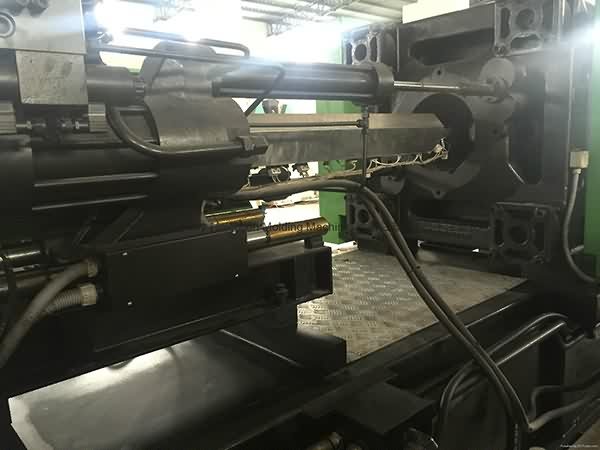

Taiwan Donghua 320t injection molding machine (Variable pump).

YoutubeVideo: https://youtu.be/6LtP9BF6UnA

Model: TTI-320F2V.

Year: 2012.

Screw diameter: 55mm.

Tie bar spacing: 660x660mm.

Machine is in good running condition with variabl pump. Interested customer can inspect machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Wholesale Discount Donghua 320t (variable pump) used Injection Molding Machine for Pretoria Factories, The product will supply to all over the world, such as: Melbourne , Czech Republic , Armenia , We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

https://elitemachinerysystems.com/machines/injection-molding/1999-85-ton-engel-vertical-single-station 1999 85 Ton Engel Vertical Injection Molding Machine ...

We are the manufacturer who was founded in 1976 and has been manufacturing and selling dies and plastic parts. We develop our business mainly in Japan. Our motto is to focus on improvement of the quality of dies for plastics and plastic parts and to make products without compromise. We, who have thoroughly mastered the knowledge of dies, deliver low-priced yet high-quality products for dies and parts necessary for mass production of automobiles, motorcycles, outboard engines, home electronics, and housing components. In addition, for quality control, we have various inspection facilities including three-dimensional measuring instruments and established the checking system to prevent defective moldings. We respond to customers' needs by the one-stop production system that performs trial production, die making, resin part manufacturing and delivery as well as by our highly value-added products. If you wish to have a quick delivery, cost reduction and high quality, please contact us.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!