Wholesale JSWJ1300EIII used Injection Molding Machine for Swansea Manufacturers

Wholesale JSWJ1300EIII used Injection Molding Machine for Swansea Manufacturers Detail:

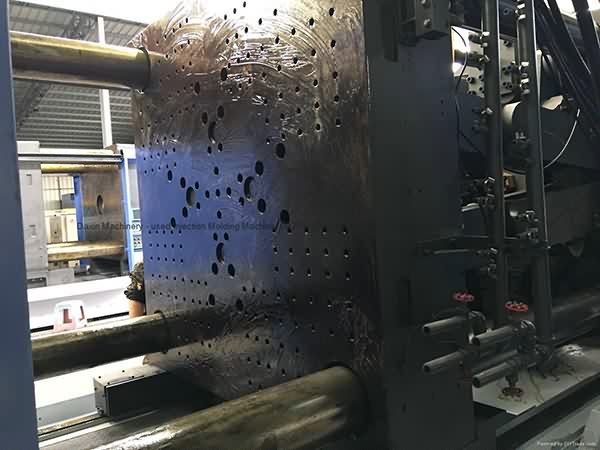

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Wholesale JSWJ1300EIII used Injection Molding Machine for Swansea Manufacturers, The product will supply to all over the world, such as: Algeria , Kenya , Cologne , To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

MMC Packaging can develop systems for after-moulding functions specific to your unique operation. Engineered for cost-effective efficiency, MMC equipment can assemble multiple-piece closures.

For more information, please contact us: consultmmc@mmcpackaging.com

www.mmcpackaging.com

Injection molding of a pen cap connector part from raw materials to finished pen cap part. This video features my new injection molding setup utilizing a 1 ton ...

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.