Wholesale ODM 30 Tons Industrial Vertical Mini Plastic Injection Molding Machine

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Wholesale ODM 30 Tons Industrial Vertical Mini Plastic Injection Molding Machine, We, with great passion and faithfulness, are willing to provide you with perfect services and striding forward with you to create a bright future.

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Mini Injection Molding Machine, Plastic Injection Molding Machine, Vertical Plastic Injection Molding Machine, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

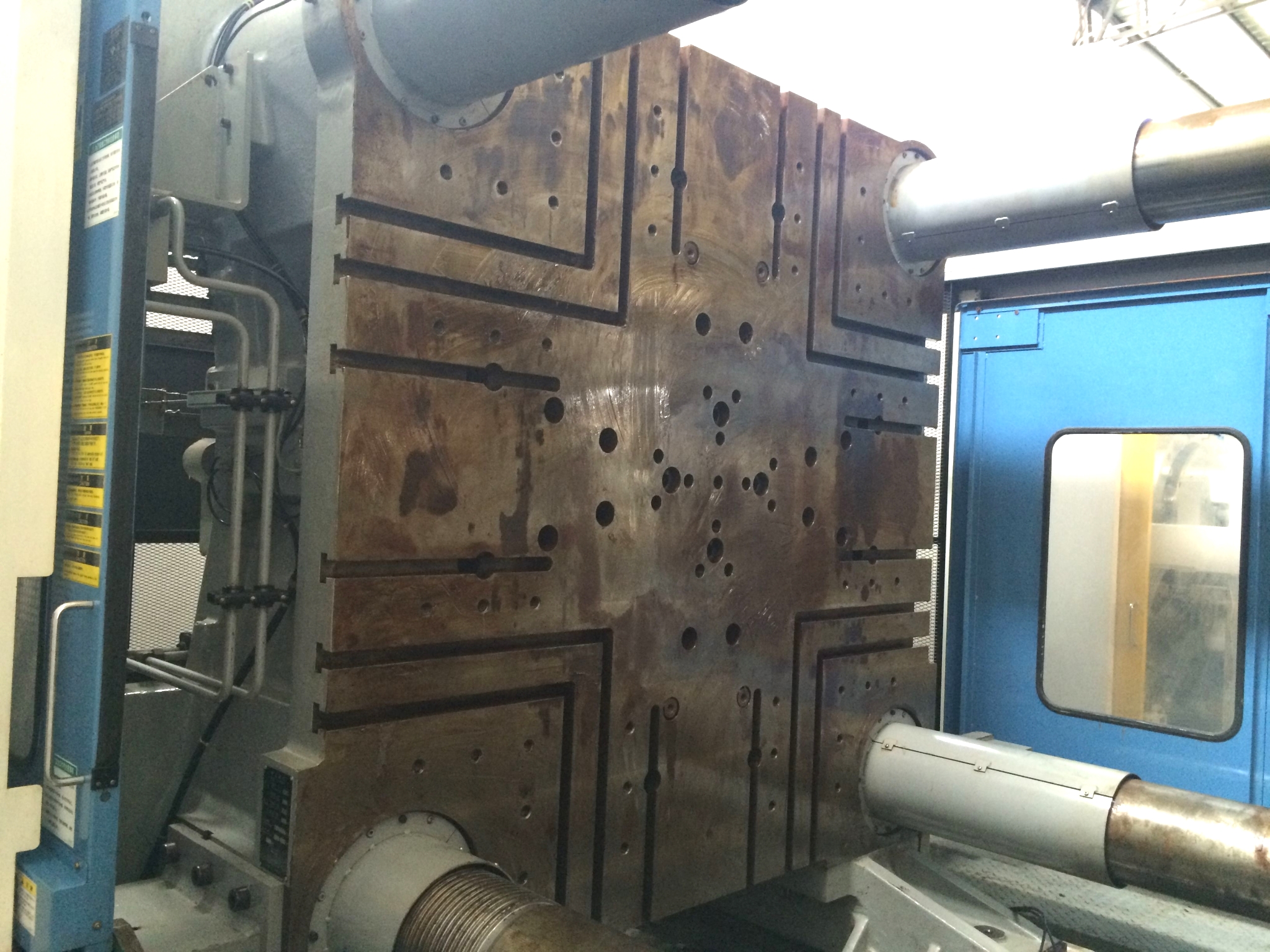

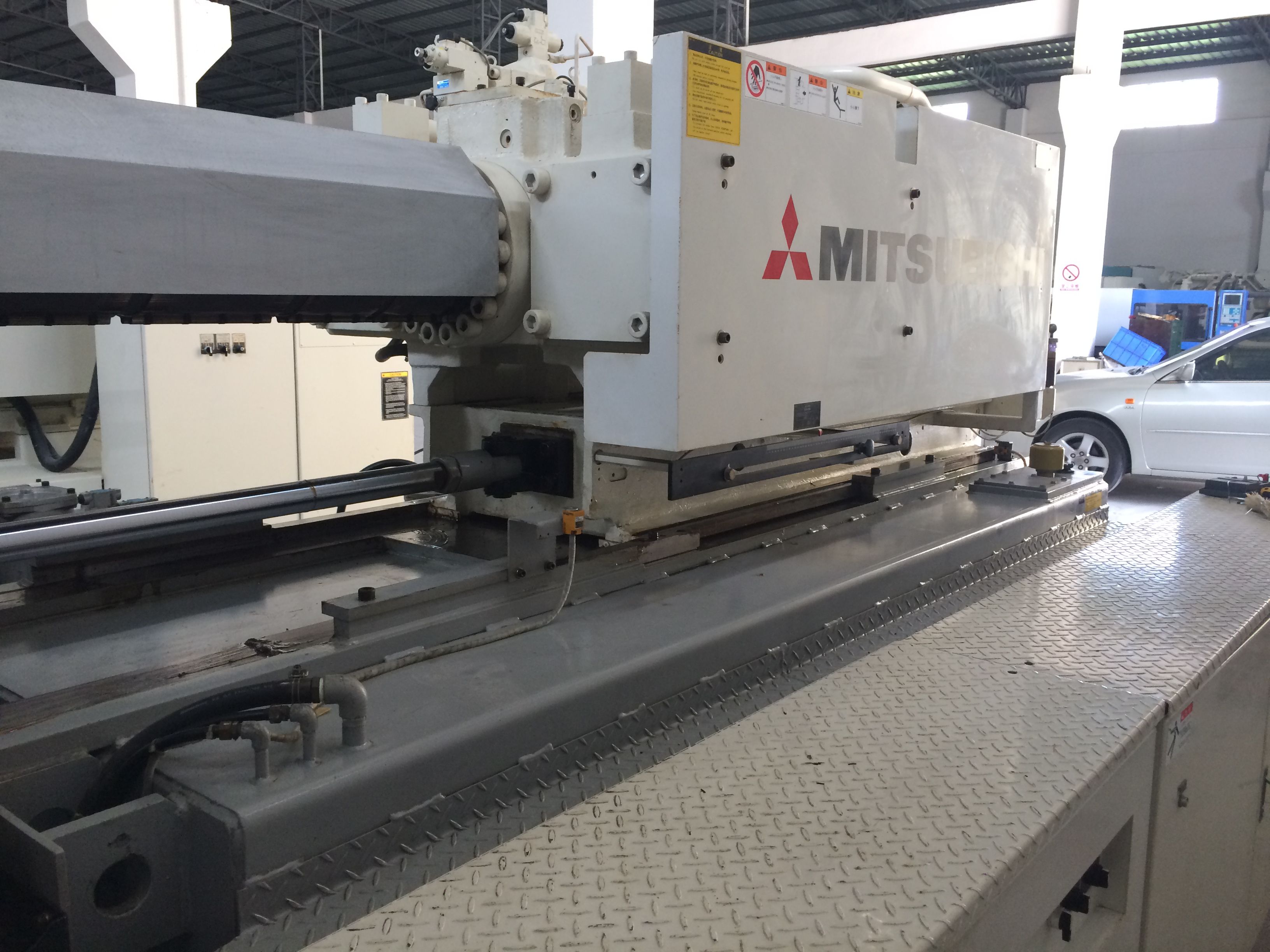

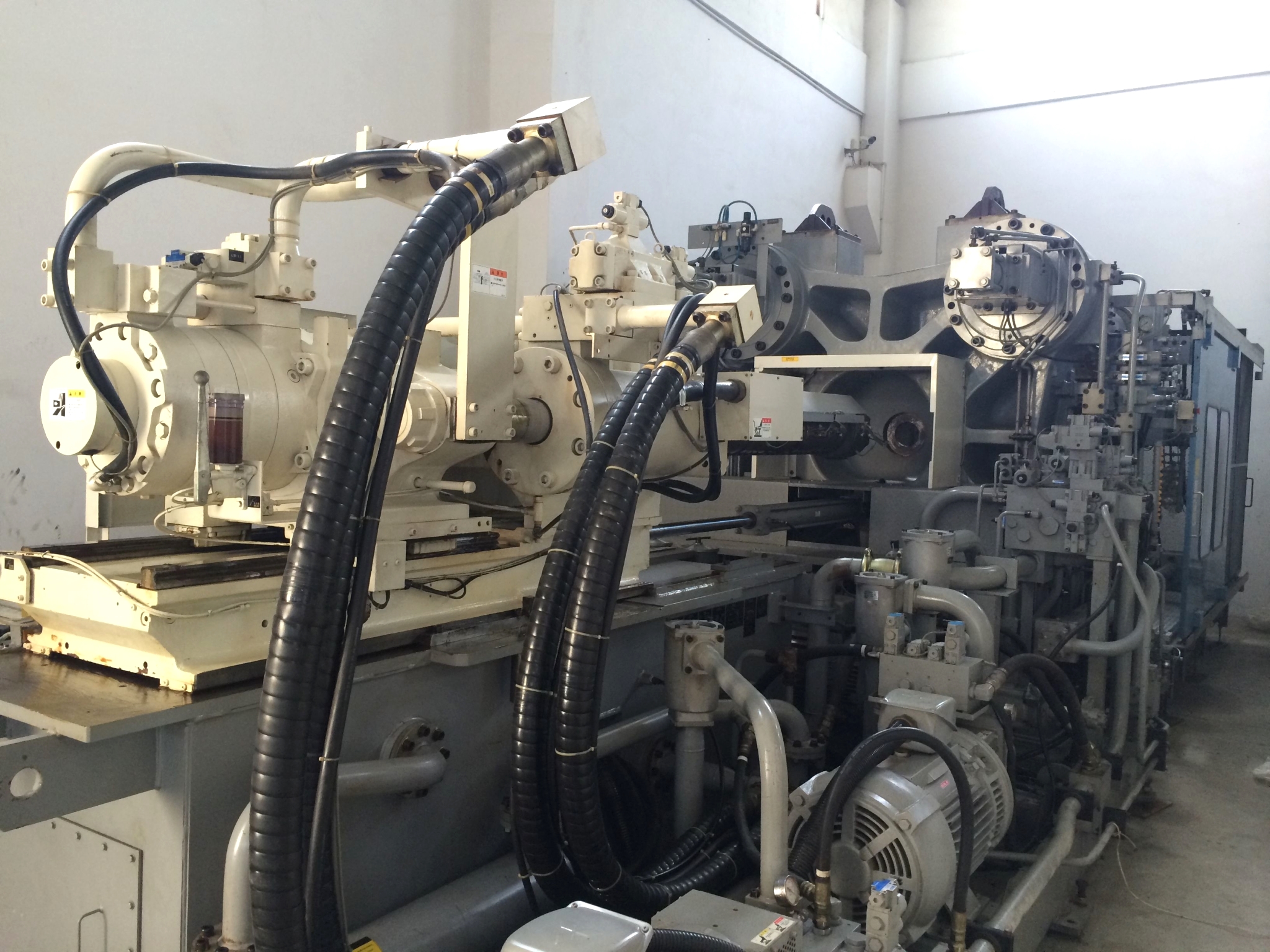

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Why choose Daxin?

- Wide range of machines: Over 200 machines (20-2000t) in 10000 sqm warehouse (Largest collection of Japanese machines in China)

- Rich experience in export: one-stop solution including dismantling of machines, loading, moving, custom clearing (many agents cannot clear custom for used machines), shipment, assembling and commissioning of machines.

- All machines can be powered on for test-run. All machines can be viewed under one roof in our warehouse.

- Post-sale support: providing spare parts, commissioning machine, inputting program, repairing PCB boards or other machine parts

- Quality assured: All machines parts are checked thoroughly, including pumps, toggle, screw, barrel, oil seals, ball bearing, platen.etc.

- Any defective parts are repaired or replaced if beyond repair.

- Have exported to more than 30 countries : South East Asia, South Asia, Australia , Middle East, Africa, South America, Central America.

Product Image

INJECTION MOULDING MACHINE FOR THERMOPLASTICS

PRESSE AD INIEZIONE PER TERMOPLASTICI

www.plasticmetal.it

Electric motor Armature repair, NEVER TRY THIS EVER! Electricity can and will kill you if your are not careful, if you have a bad armature, replace it, do not try to repair it, this only shows you the mechanics of an armature and this probably won't last long. I ended up using a brass brush instead, the copper did not last long, and don't forget to clean your graphite brushes with light sanding. I also put a heat resistant ring around both ends of the armature brushes cut out of tubing and glued them in, this worked good at holding the brush in place. Any time you experiment with motors they can hold a spark for a long time after you are done so make sure you watch your project for a while after to prevent any fire hazard. Again don't ever do this just replace the armature with a brand new one, or better yet get a new tool. The cost for a new tool is similar to an armature cost, this is desert island science, for those people stranded on an island with nothing but spare parts. keep inventing'