Wholesale Price China Mitsubishi 1300t Used Injection Molding Machine – Sumitomo Used聽 Injection Moulding Machine

Wholesale Price China Mitsubishi 1300t Used Injection Molding Machine – Sumitomo Used聽 Injection Moulding Machine Detail:

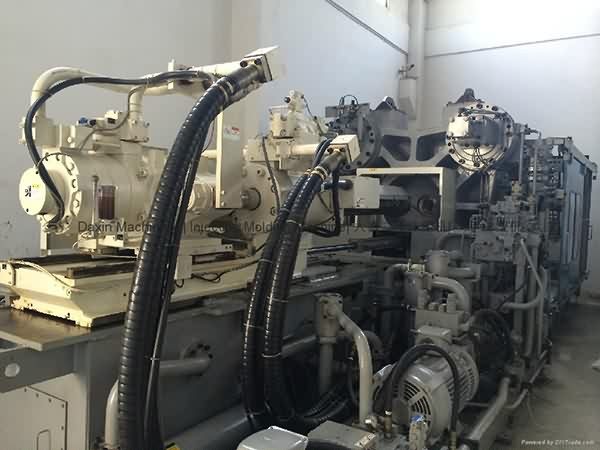

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Wholesale Price China Mitsubishi 1300t Used Injection Molding Machine – Sumitomo Used聽 Injection Moulding Machine, The product will supply to all over the world, such as: South Korea , Ottawa , Mozambique , Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

TCM BALER:https://www.tcmbaler.com/ a professional manufacturer, specialize in hydraulic compressing machine/ baling press compactor/pressing baler for more than 15years, Our products are applicable for waste cardboard/ cardbox, OCC, plastic bottles ,fiber, rags,wipers,used clothes/clothing,textiles, cotton, newspaper, kraft paper, scrap metal, mattress spring, scrap car body, heavy steel etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.Fully automatic horizontal baling press

2.Semi-automatic horizontal baling press

3.vertical baling press baler

4.wipers/rags bagging press baler

5.scrap metal baling compactor

6.shearing baler machine

7.container shear

8.movable scrap metal baler compactor

9.single shaft shredder

10.double shaft shredder

https://www.tcmbaler.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: machineinchina@hotmail.com

Plastic Baler, Plastic Baler Suppliers and Manufacturers Austria, Baler Machine For Cloth, Plastic Baler, Wholesale Various hydraulic plastic baler used clothes baling press machine for sale. 2017 Hot sale plastic bottle baler, , Hydraulic Textile Press Baler, Plastic Bottle Baler Machine, Plastic Bottle Baler Machine Bangladesh, Textile Vertical Compactor, Plastic Bottle Baler Machine, Tire Baler Machine For Sale, Plastic Bottle Press Machine For Sale. Baler machine for used clothing plastic bottle baler machine., Used Clothes Baler, waste metal machine Second hand clothes baler Bulgaria, Clothes And Textile Compress Baler Machine, plastic bottle baler waste metal machine Second hand clothes baler . 20721 Results Used scrap plastic baler, baling machine for sale, , Used Clothes And Textile Compress Baler Machine, Baler Rental Recycling Equipment for Business, Republic Bhutan, Used Clothes And Textile Compress Baler Machine Clothes Baling Machine, Baler Rental Republic Services Plastic bottle balers, Used clothing balers, Put our industry expertise and recycling knowledge to work in selecting the right, Used Clothing Baling Machine Sponsored Listing, Baling Machine, Baling Press Machine, Waste Baler For Sale Botswana, Mini Hay Baler Machine, sometimes called used clothes baler, The perfect plastic bottle baler and aluminum can baler, also known as bottle baling machine or can press, , scrap clothing baler machine, Vertical Balers Recycling Equipment Corporation Canada, clothing baler textile baler, SUPERSTORE for New and Used Vertical Balers or Downstroke Balers for sale. Recycling Compacts aluminum cans, plastic bottles and jugs, plastic cups, , Second hand Clothing And Textile Baler Machinery, price of baling machine for hand cloth Denmark, Design Old And Secondhand Clothes Baler, HOME plastic bottle baler baling JP30LT Clothes Baler Machine Second hand Mini Pak is a small hand operated baler for baling plastic, Design Old And Secondhand Clothes Baler Machine, small textile used clothes vertical baler Algeria, Vertical Baler For Clothes, plastic bottle baler small textile used you need not put second hand clothes o plastic Min. bihar new model small scrap metal balers for sale., Used Textile And Clothes Hydraulic Press Packing Baler Machine, Used Balers, Recycling Equipment Corporation 267 218 7200 Ecuador, Hydraulic Vertical Cotton Baler, Plastic, Corrugated, Metals, Clothing, etc When it comes to buying or selling a Used Baler or looking for Used Balers For Sale, , Used Clothes Hydraulic Press Baler Machine, Vertical Bottle Can Balers WasteCare Corporation Micronesia, Textile And Cloth Baler Machine, Vertical Bottle and Can Balers plus other Recycling and Waste ready for sale or Aluminium Cans or 2, 000 Plastic Bottles of expired, Hot Sale Used Press Clothes Baler Machine, Plastic Baler ads in South Africa, Junk Mail Classifieds Haiti, Vertical Press Baler Used Clothes Packing Machine, View our Plastic Baler adverts in South Africa at Junk Mail Classifieds, Hydraulic Used Clothes Baling Machine, Secondhand plastic package baler packing machine Hydraulic Hungary, Clothes Bale Press, Secondhand Plastic Bottle Baler Packing defective plastic, PVC, PE, P clothes baler machine, compress baler how to find a second hand baler machine in, Vertical Clothing Packer Clothes Bales Packing Machine, Long Stroke Balers, PET Bottle Baler, Hollow Plastic Baler Ireland, Clothes Compressing Machine, eg. Hollow Plastic Baler, PET Bottle Baler, Aluminum Can Baler Swivel Twin Lifting Chamber Baler. Recycle clothing, used clothes, textile waste, , Textile Cotton Baling Press, Balers for Paper, Plastic and Cardboard at Just Recycling Iraq, Used Clothing Waste Cotton Vertical Hydraulic Baler For Sale, Balers for Paper, Plastic and Cardboard 2004 BOA Baler 2100 with BOA Conveyor For Sale BOA Baler and Conveyor NOW SOLD 2004 BOA plastic bottles, Texitle Baler, Compactors, Balers, Compaction Plus Iceland,

Here an Engel Speed 380/70 machine is injection moulding airline cups using automation from Waldorf Technik and a mould from Otto Hofstetter.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!