Wholesale Price China Toshiba IS650GT Used Injection Molding Machine to Palestine Manufacturers

Wholesale Price China Toshiba IS650GT Used Injection Molding Machine to Palestine Manufacturers Detail:

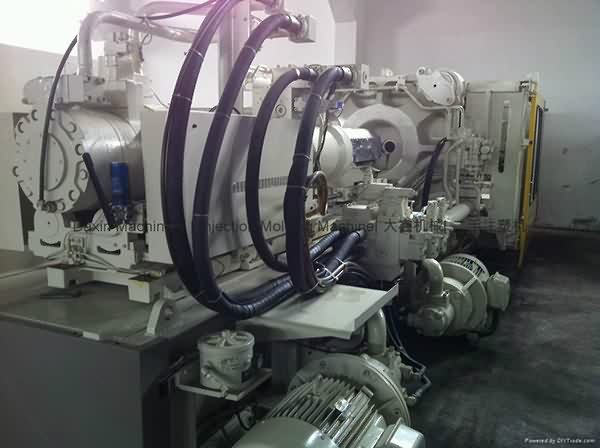

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for Wholesale Price China Toshiba IS650GT Used Injection Molding Machine to Palestine Manufacturers, The product will supply to all over the world, such as: Marseille , Netherlands , Guyana , Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

Huaao Electricity Technology Co.,Ltd is the only supplier who professional produce: APG machine,APG molds,casting mold and instrument transformer winding ...

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.