Wholesale Price CLF-200TY used Injection Molding Machines to Paris Factory

Wholesale Price CLF-200TY used Injection Molding Machines to Paris Factory Detail:

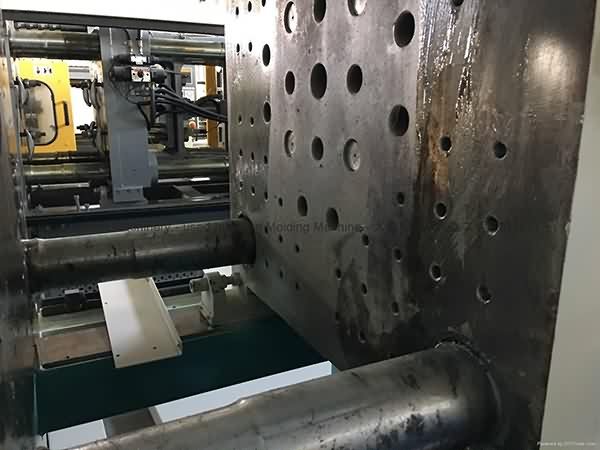

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Wholesale Price CLF-200TY used Injection Molding Machines to Paris Factory, The product will supply to all over the world, such as: Jordan , Colombia , Frankfurt , We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

To contact the seller and view more details, visit https://www.listatool.com/listings/victor-uh-1-horiz-vertical-combination-miller

40,000Lb Erickson Die Handler Truck For Sale https://affordable-machinery.com/used-die-handlers-trucks-carts-sale/ click the link to go to our website to see more information. We buy and sell used die handlers. Contact us at 616-200-4308.

https://youtube.com/watch?v=mB-30_aIPTw

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.